Every thriving business organization heavily relies on the overall health of its equipment. Your organizations’ equipment offers great assistance to your workforce by automating and streamlining some of the most mind-blowing workflows, so keeping an equipment maintenance log book to have all your company equipment in top-notch condition is crucial.

- What Is an Equipment Maintenance Log? Part 1

- Importance of an Equipment Maintenance Log Part 2

- How to Use an Equipment Maintenance Log Part 3

- Equipment Maintenance Procedure Best Practices Part 4

- Equipment Maintenance Log Form Template Part 5

Part 1

What Is an Equipment Maintenance Log?

Equipment maintenance log is a business document that monitors all the activities that transpire during a system checkup procedure. Typically, it precisely documents which employee did what, the exact time the action was procured and for what reason was the specific activity was carried out.

Incredibly detailed, an excellent equipment maintenance log captures a wide array of aspects of your organizations’ machine like:

- Technician in charge the specific machine as well as the maintenance procedure

- Last checkup date

- Observations made during the checkup

- Recommendations made after the checkup

- Next scheduled for the maintenance procedure

- Date of purchase

- Date when it began operating

- Manufactures details

- Serial no of the equipment

Essentially, this insightful document provides a brief history of equipment thus giving you a clear picture of the real facts regarding your specific machine.

Part 2

Importance of an Equipment Maintenance Log

-

Reduces Repair Expenses

Acts as a whistle blow for impending major equipment breakdowns thus preventing expensive repairs and employee injury.

-

Helps Formulate Excellent Maintenance Schedules

Provides a historical background regarding a piece of specific equipment consequently enhancing the development of reliable maintenance programs.

-

Helps Resolve Warranty Disputes

Inclusive of authentic details like the precise date when the machine was bought as well as manufactures contacts, an equipment maintenance log helps settle warranty disputes.

-

Boosts Employee Safety

Providing exact dates when a machine was lastly serviced, managers can gauge the safety level of equipment and initiating instant maintenance procedures if the safety level goes beyond the standard level-refer to manufacturers menu.

-

Greatly Reduces Negligence Levels

Enables you in quickly identifying the specific employee in charge of equipment, consequently shortening the follow-up procedure in case of negligence.

-

Improves Resale Value

Boosts the resale value of disposable equipment by offering a detailed insightful maintenance history of a machine.

Part 3

How to Use an Equipment Maintenance Log

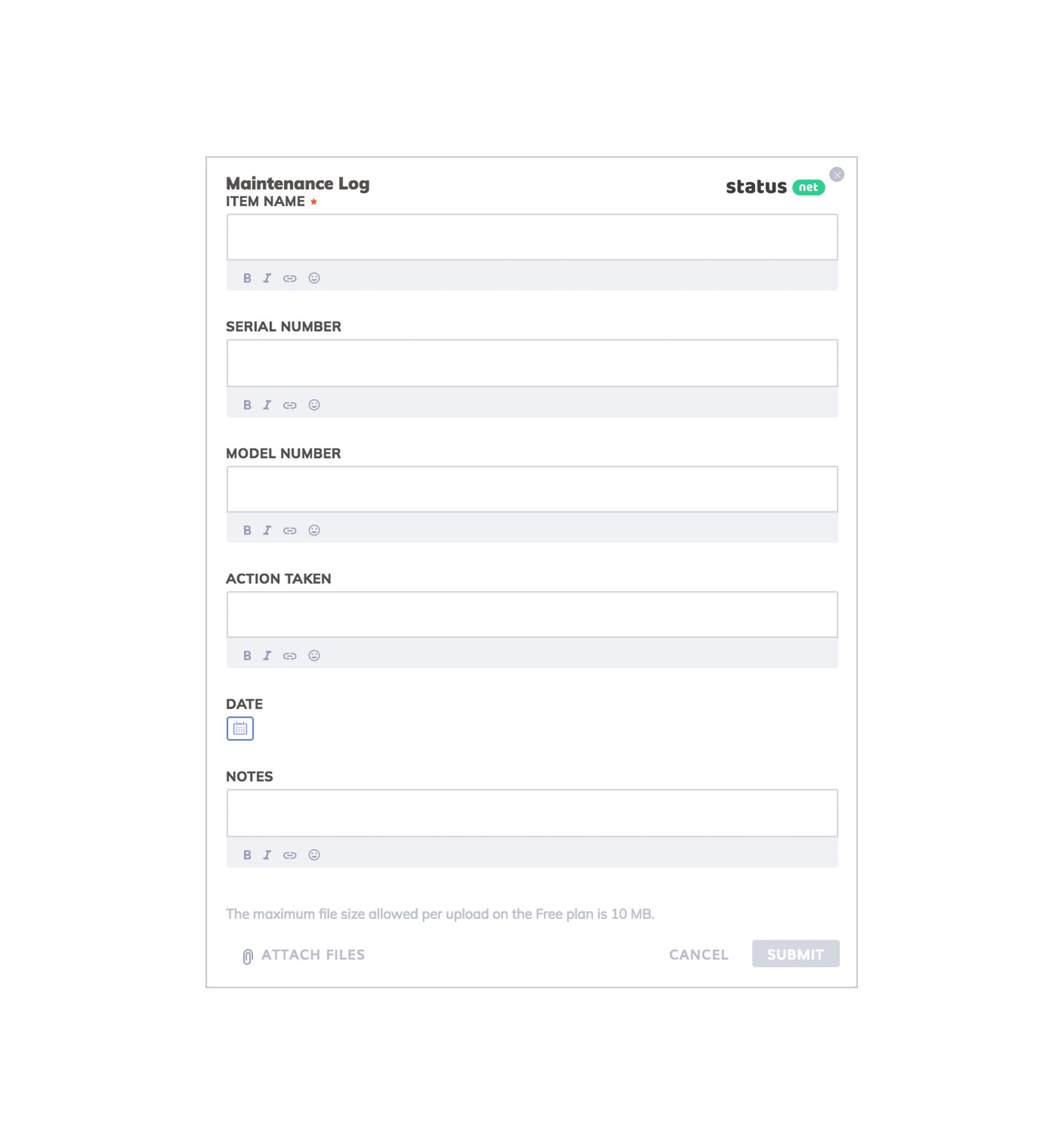

1. Fill out the Equipment’s Details

Essentially a typical equipment maintenance form includes a range of key components which starts with the main page that encompasses the details of the specific apparatus. Some of the information to consider includes:

- Name of the equipment

- Serial no of the machine

- Name of the manufacturer as well as contacts

- Date of purchase

- Start date operation (optional)

2. Note down the Observations Made

With the first section filled out, the next step is quite simple. Generally, the design of this section will depend on the number of details you want to capture.

- Date and person conducting the maintenance. Indicate your name and the specific date when you carried out the undertaking.

- Part used and what has been done. Outline the exact parts that you have checked with the subsequent observation made.

- Highlight the exact parts you have paired or replaced and finally summarize the whole recording with actionable recommendations.

- Make these recordings each time you inspect equipment.

Part 4

Best Practices When Conducting an Equipment Maintenance Procedure

An equipment maintenance procedure will keep your organizations machinery in top-notch working condition. Below are the best practices to observe when designing an equipment maintenance log:

- Keep the whole document concise and straightforward

- It is advisable to read through the manufacturer’s menu to evaluate parts of the machine to prioritize

- Besides technical check-ups, software updates are vital as well

- When recording, focus on facts

- If you are new to the specific equipment, it is always advisable to seek advice from experienced operators if you find yourself in a black spot

- After inspecting the equipment, consider providing a lasting solution to the problem encountered

Part 5

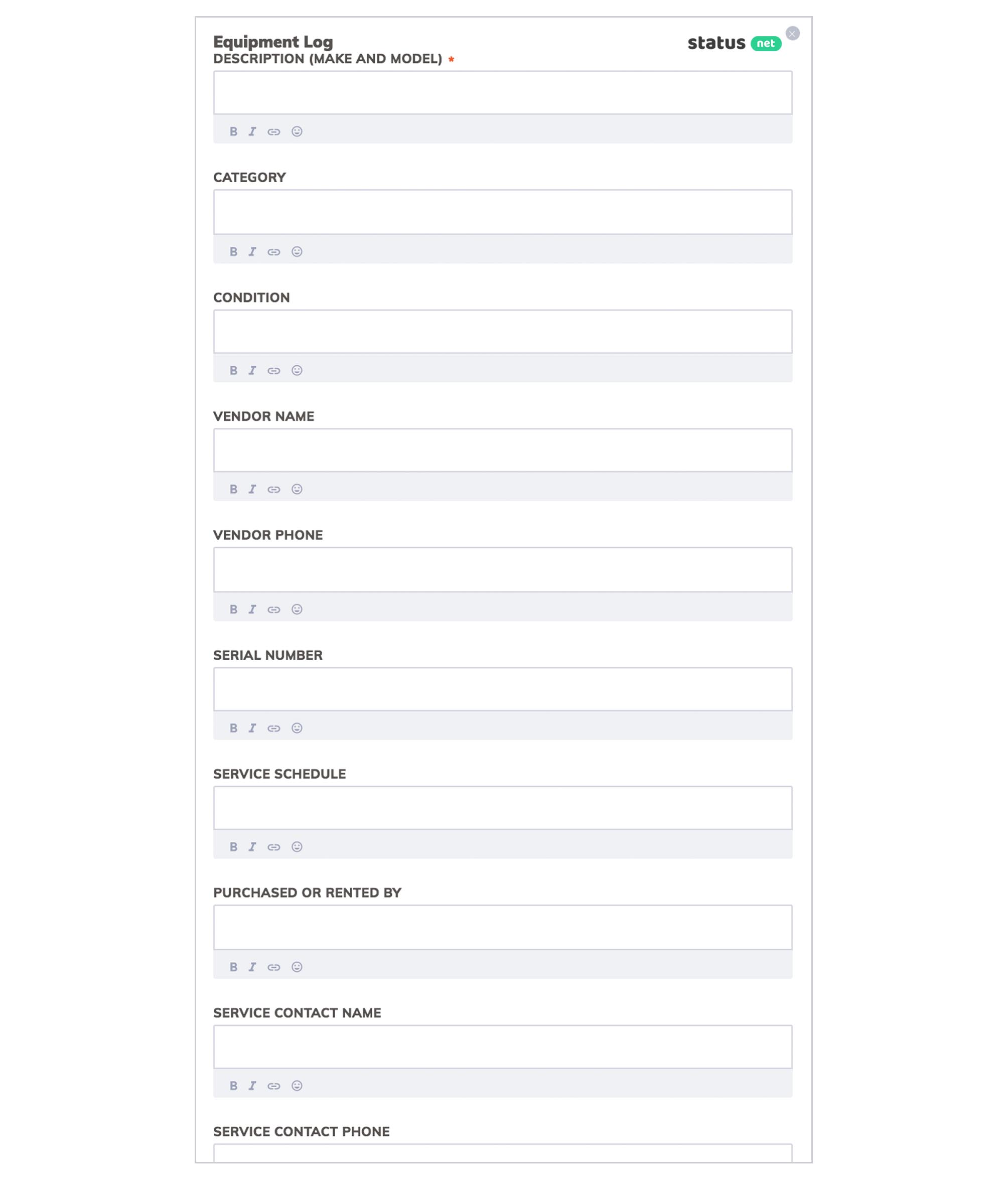

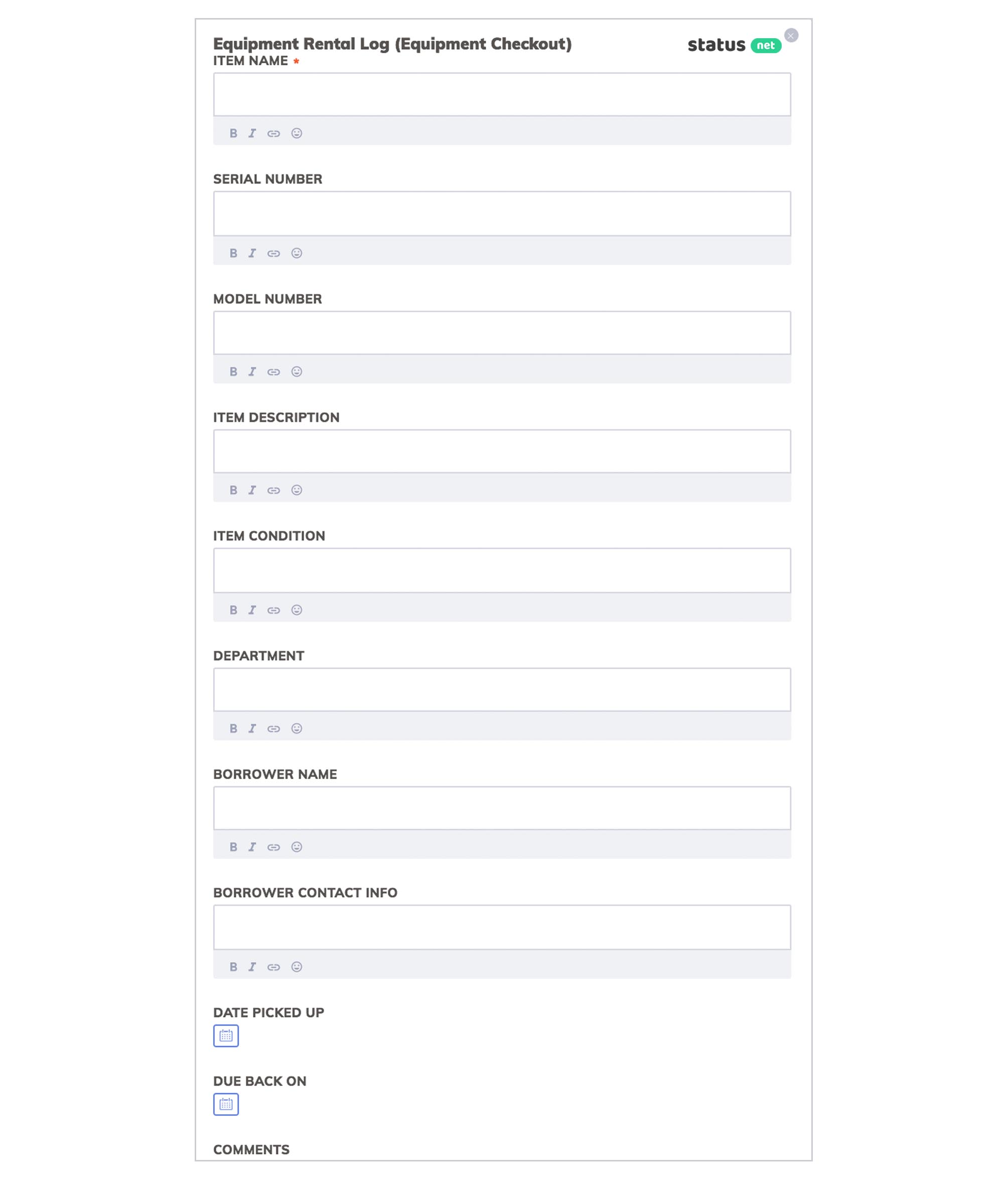

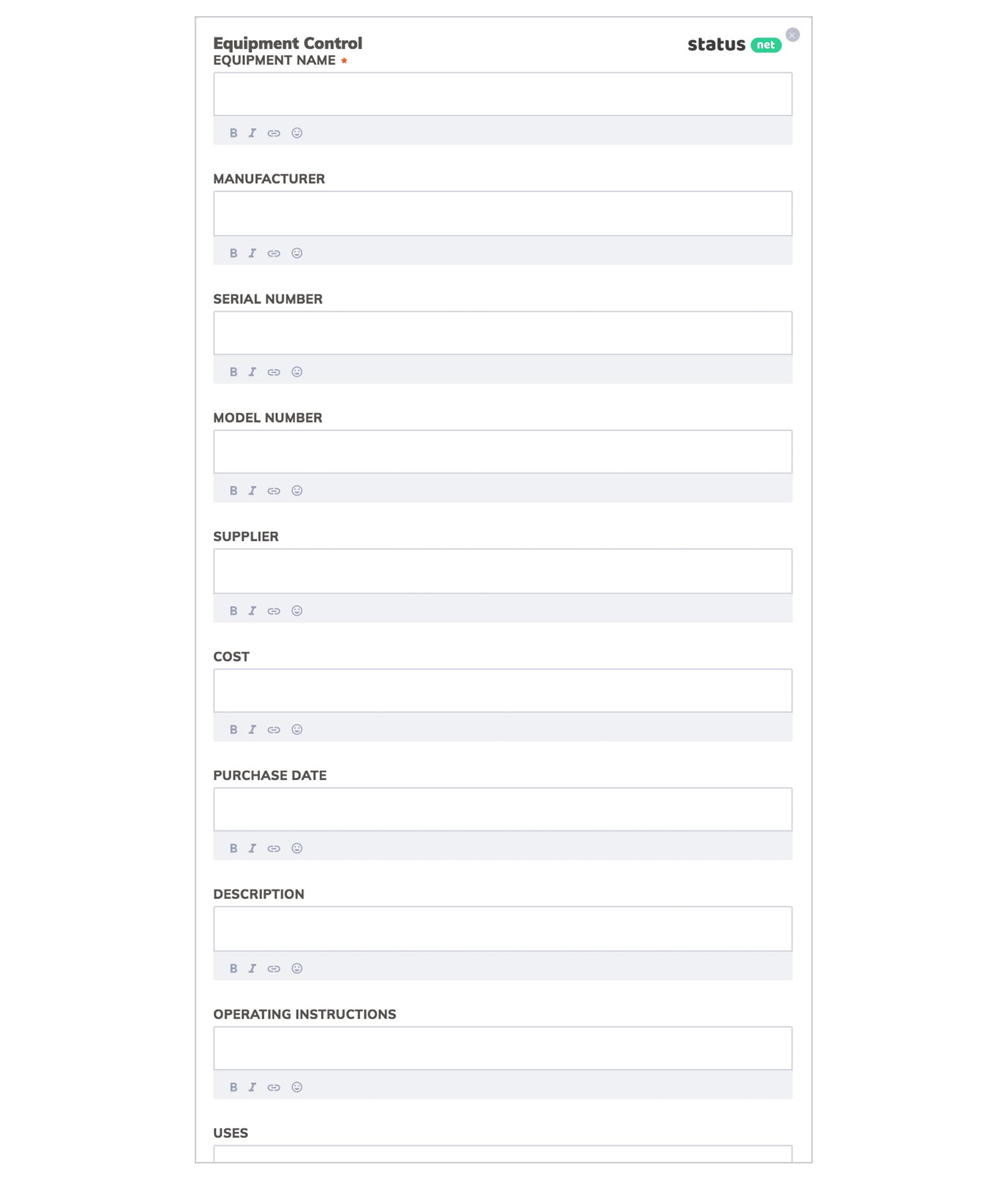

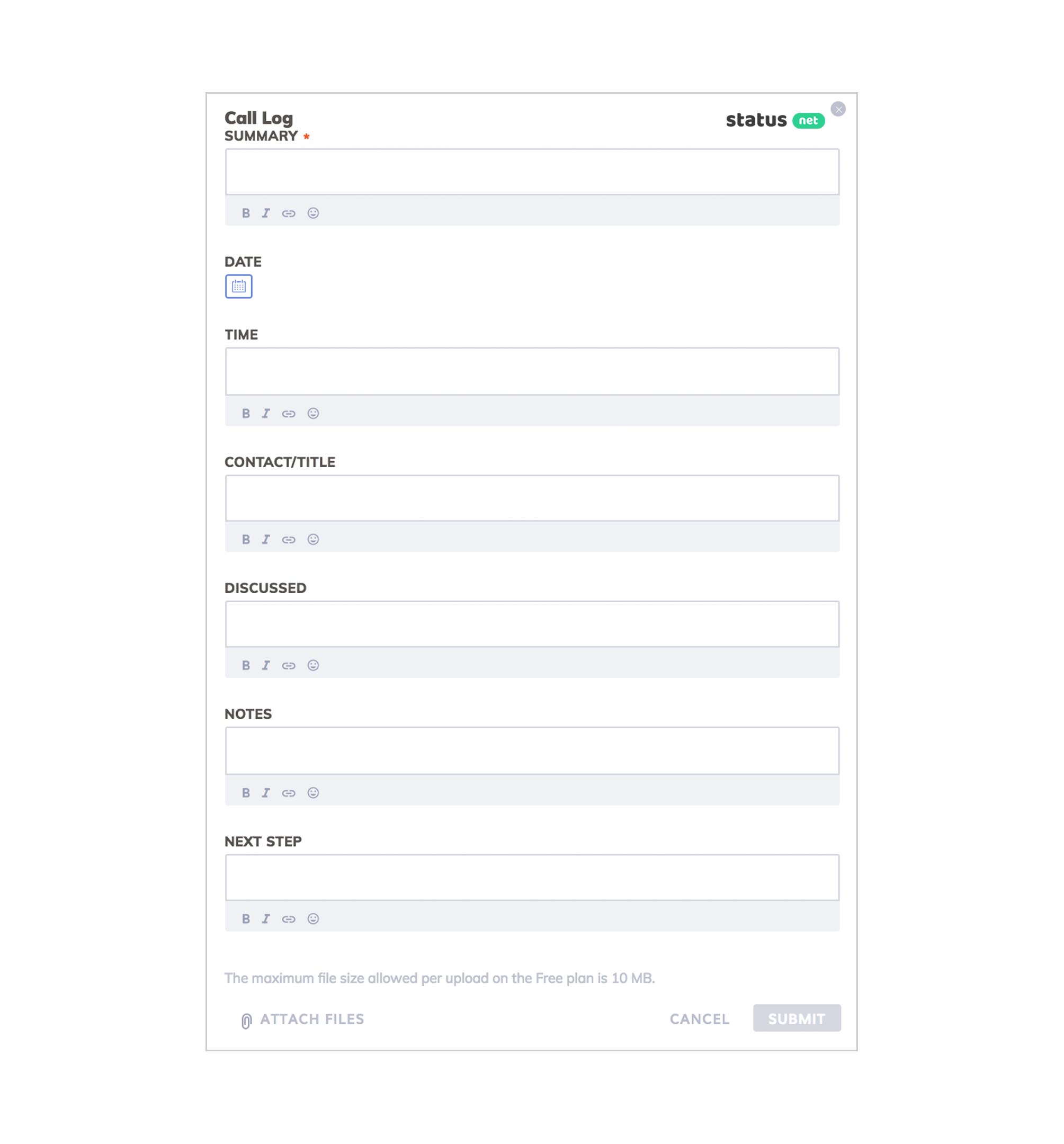

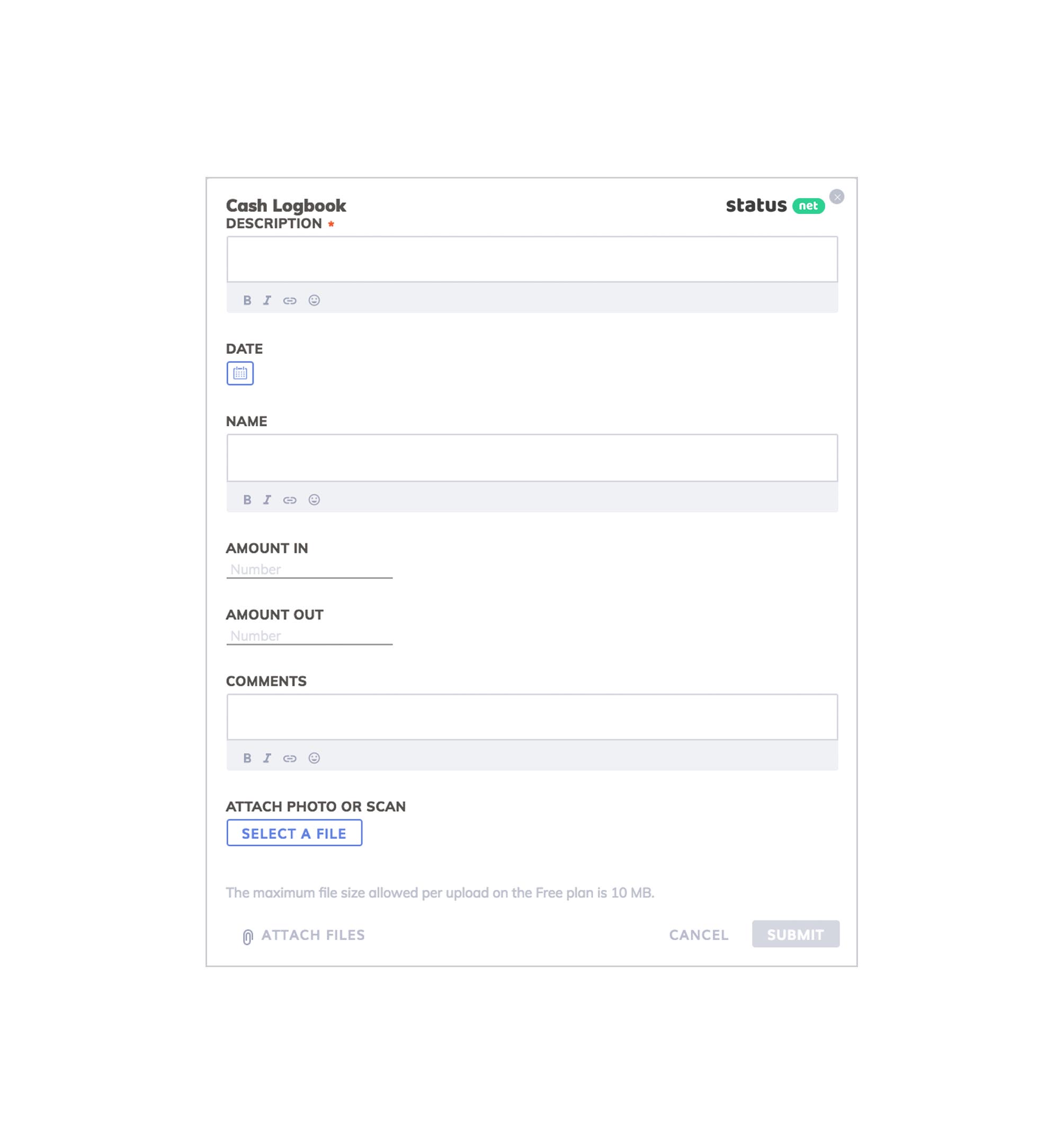

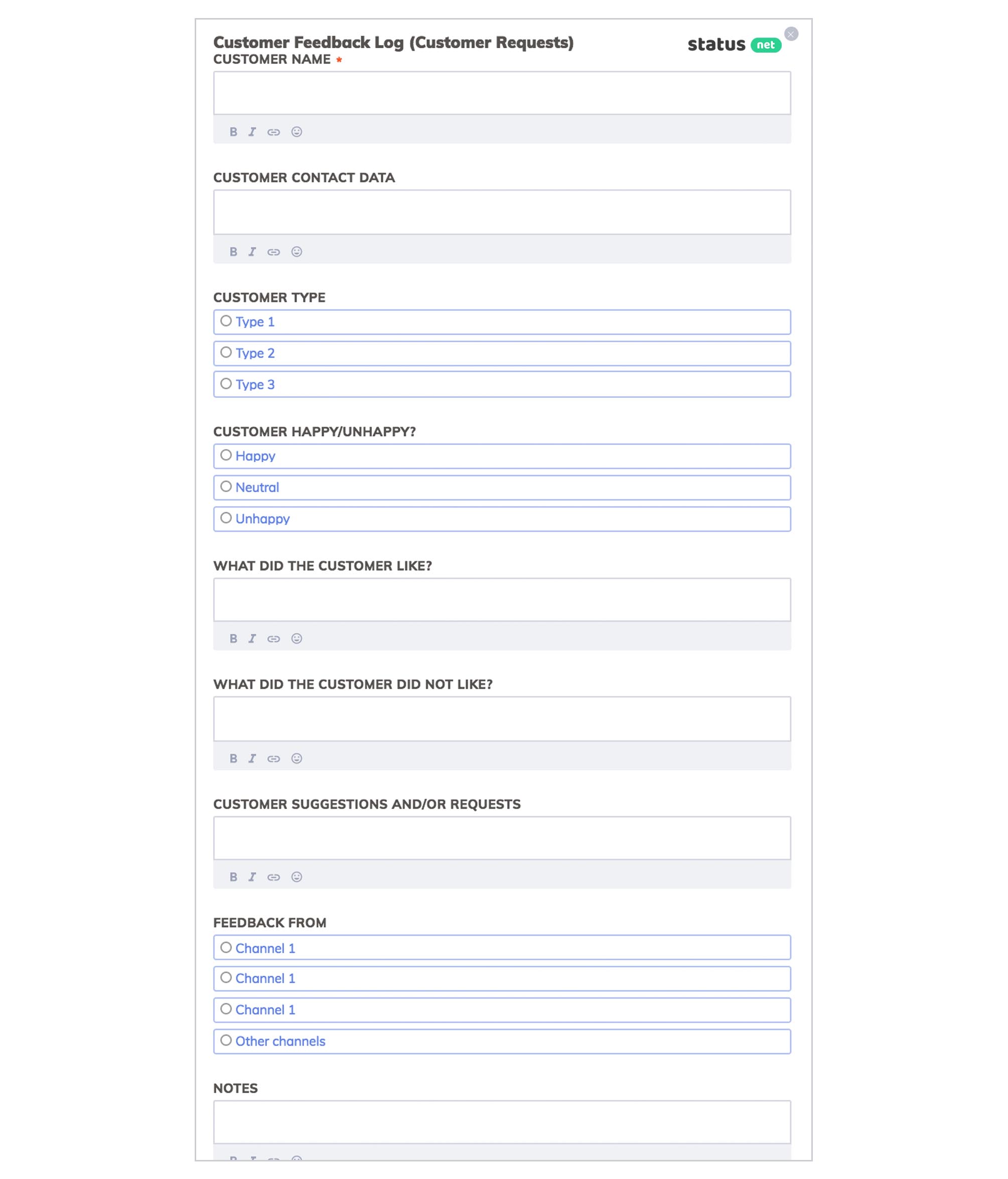

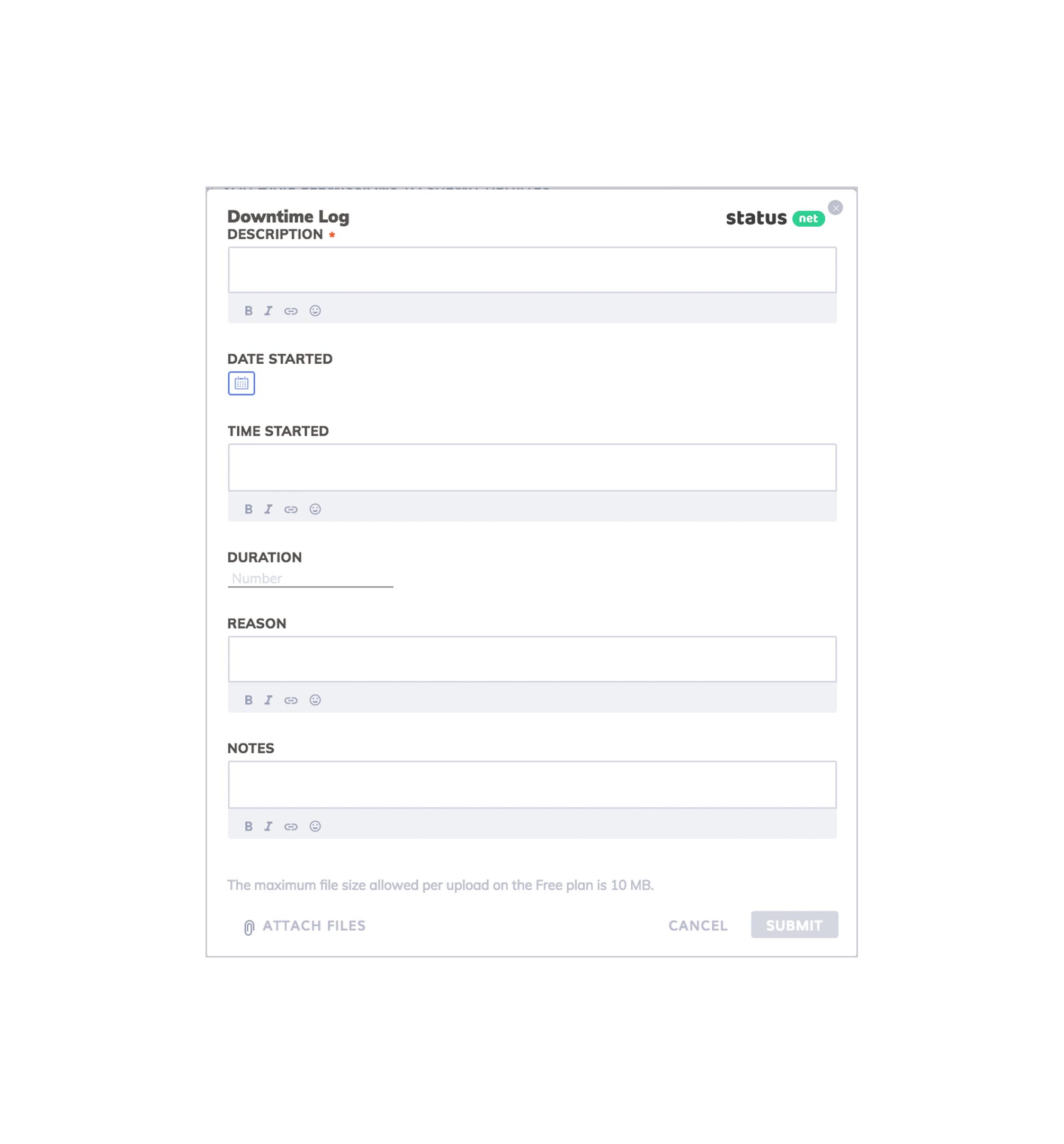

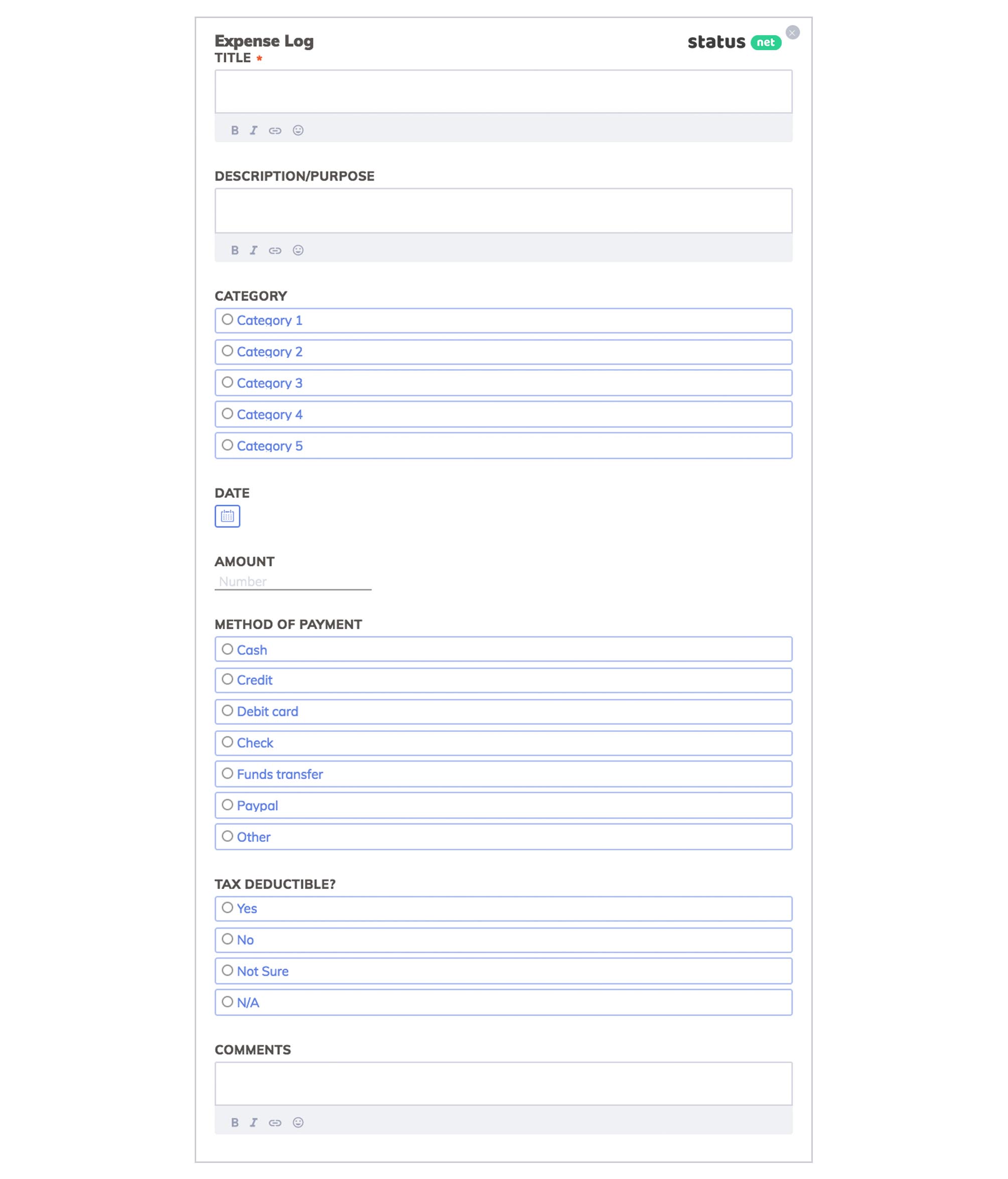

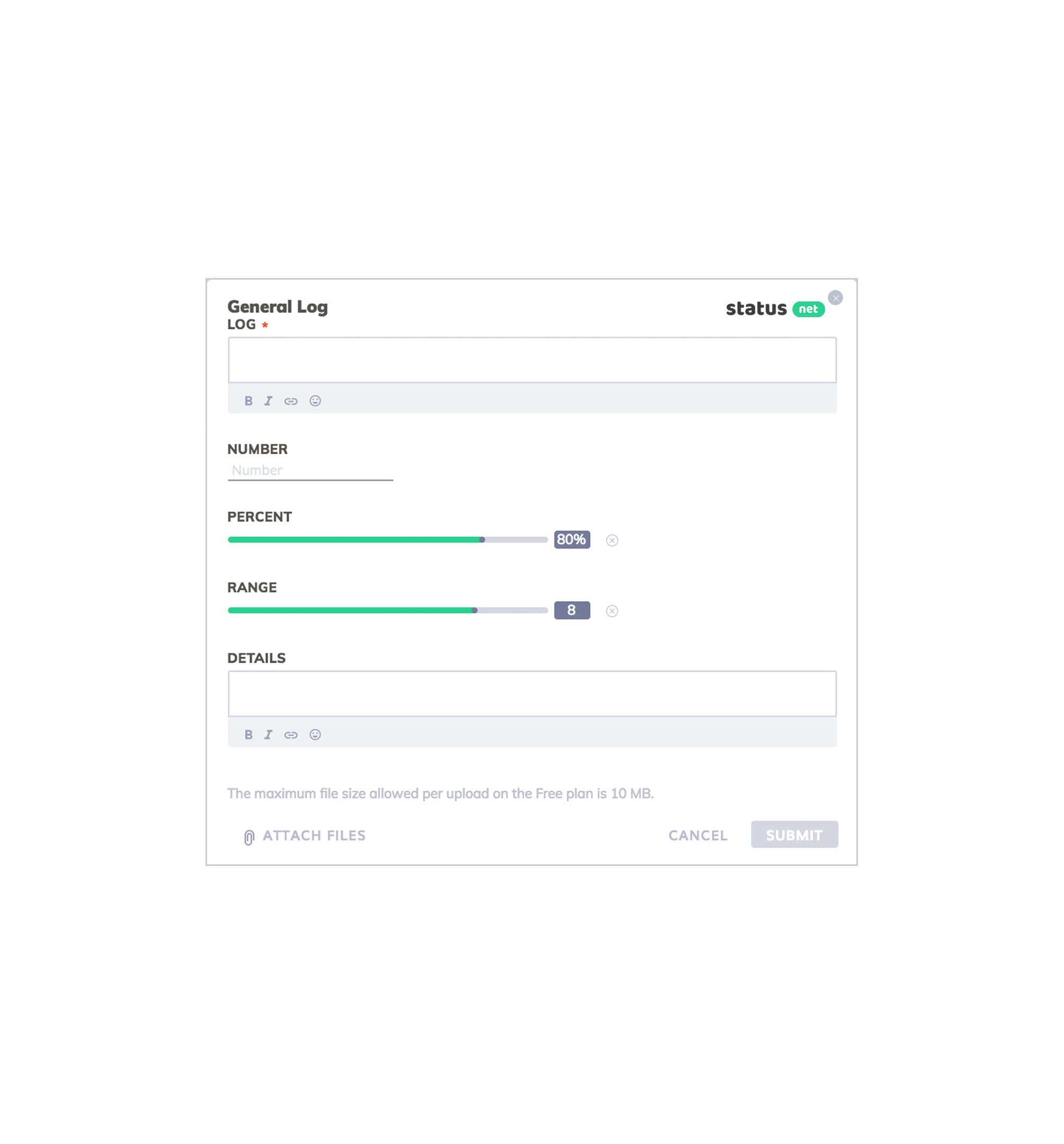

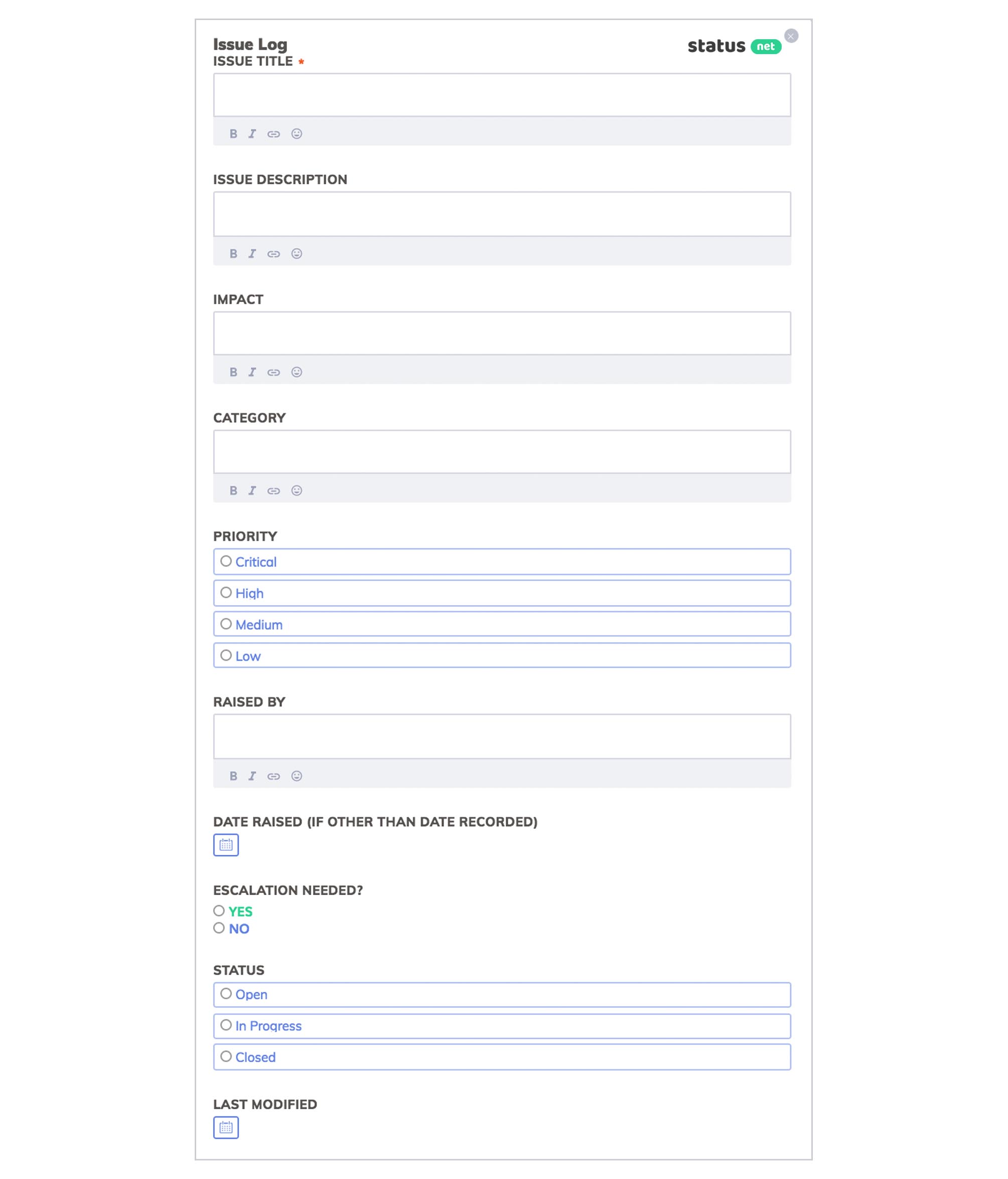

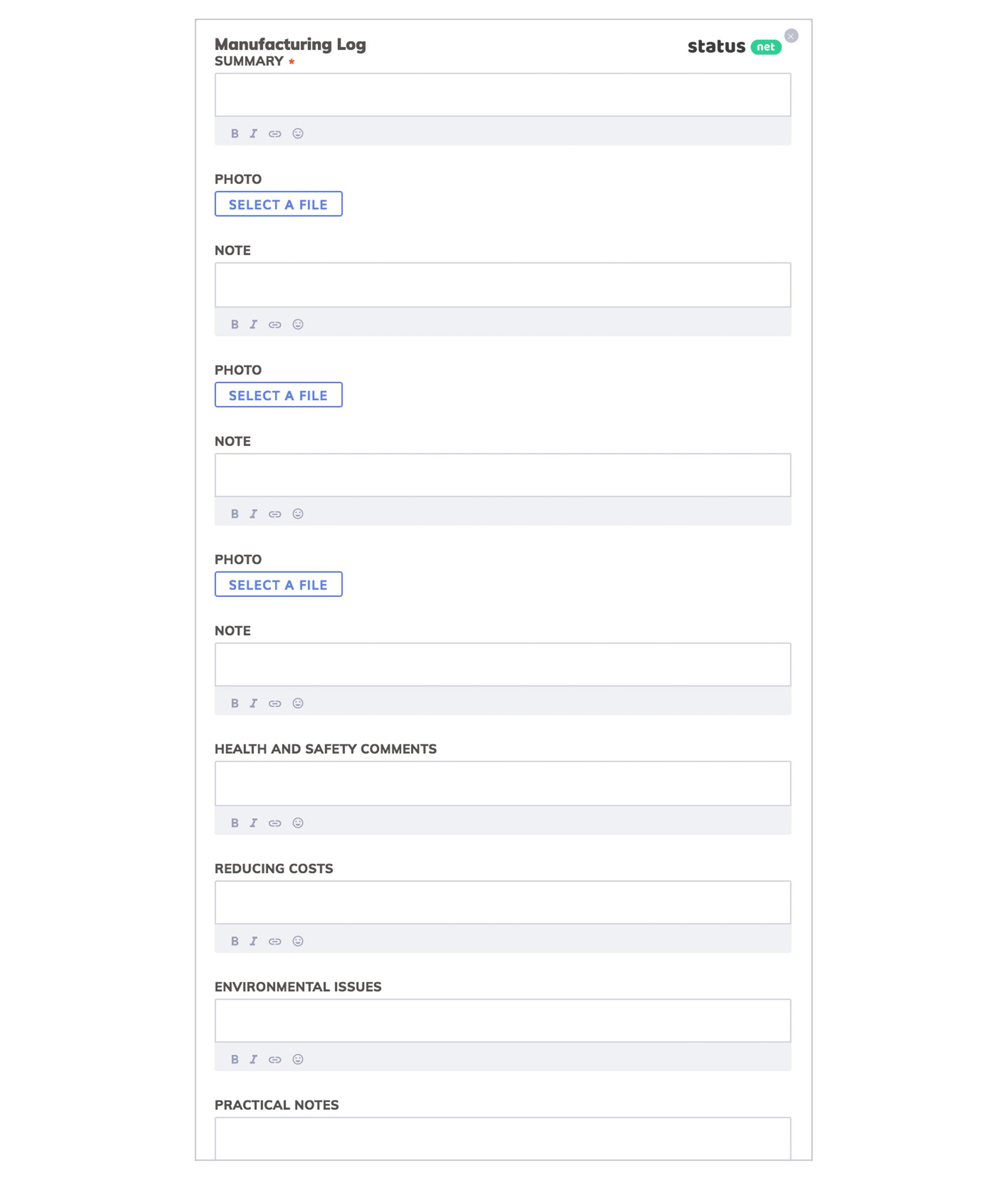

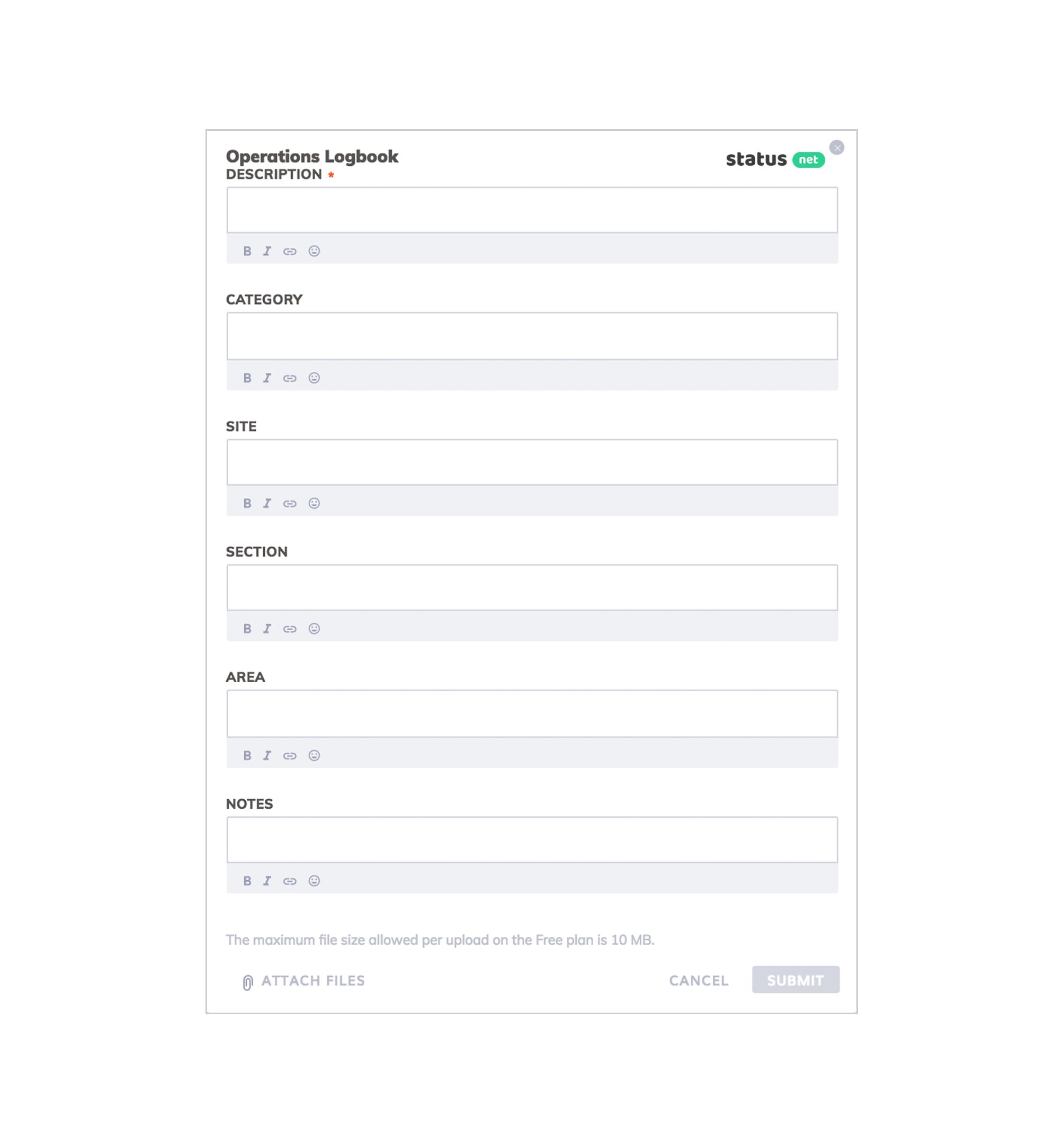

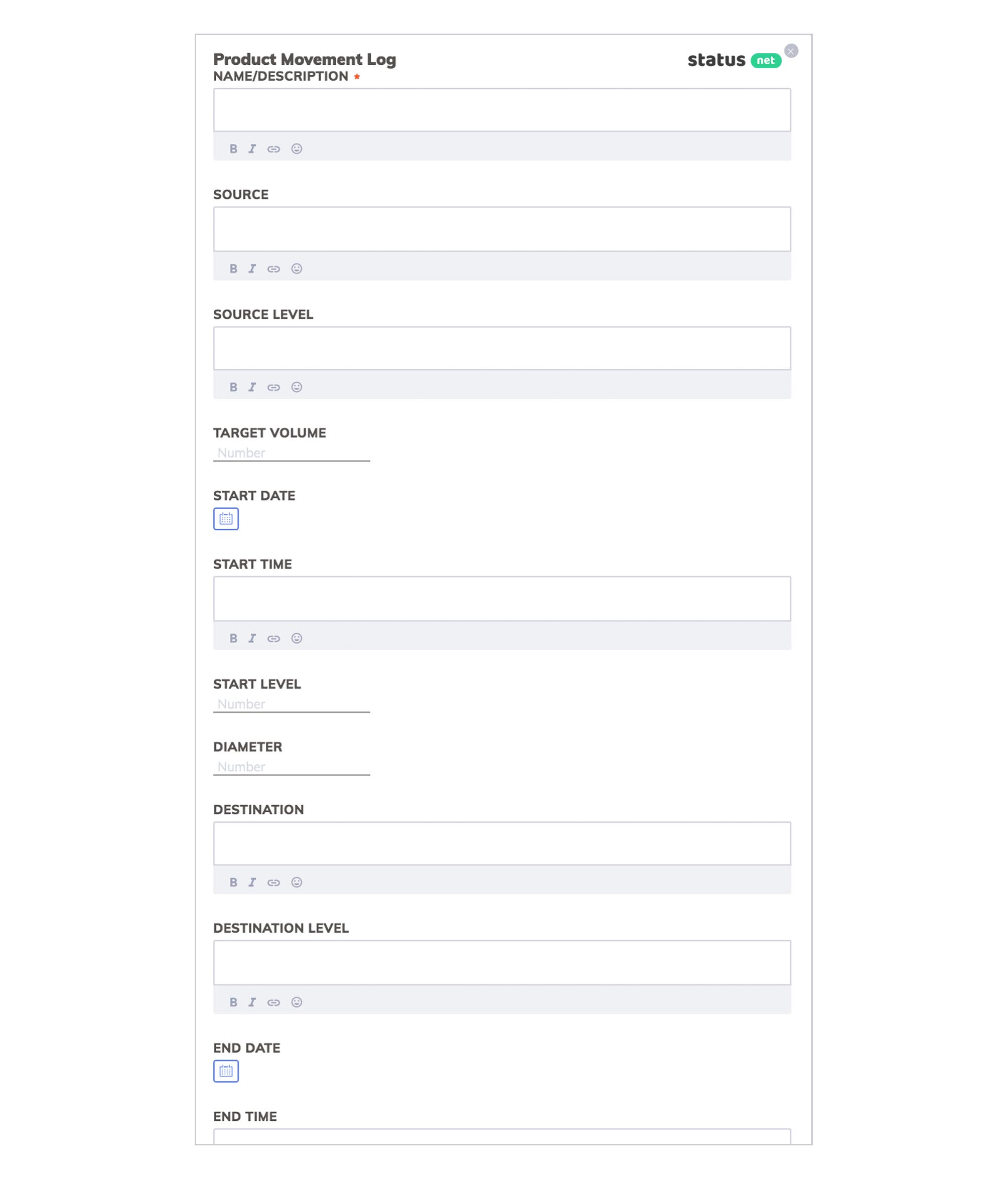

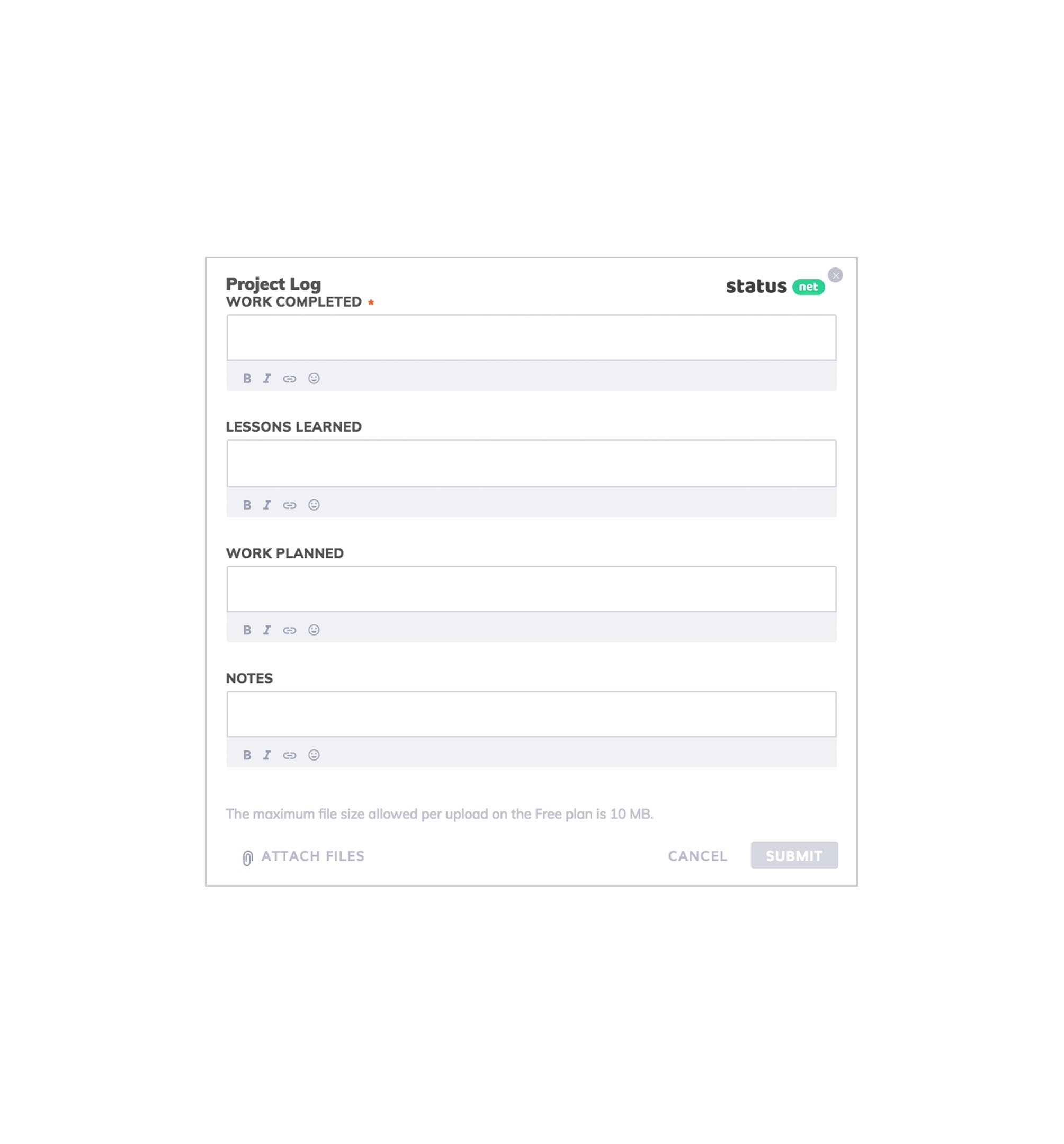

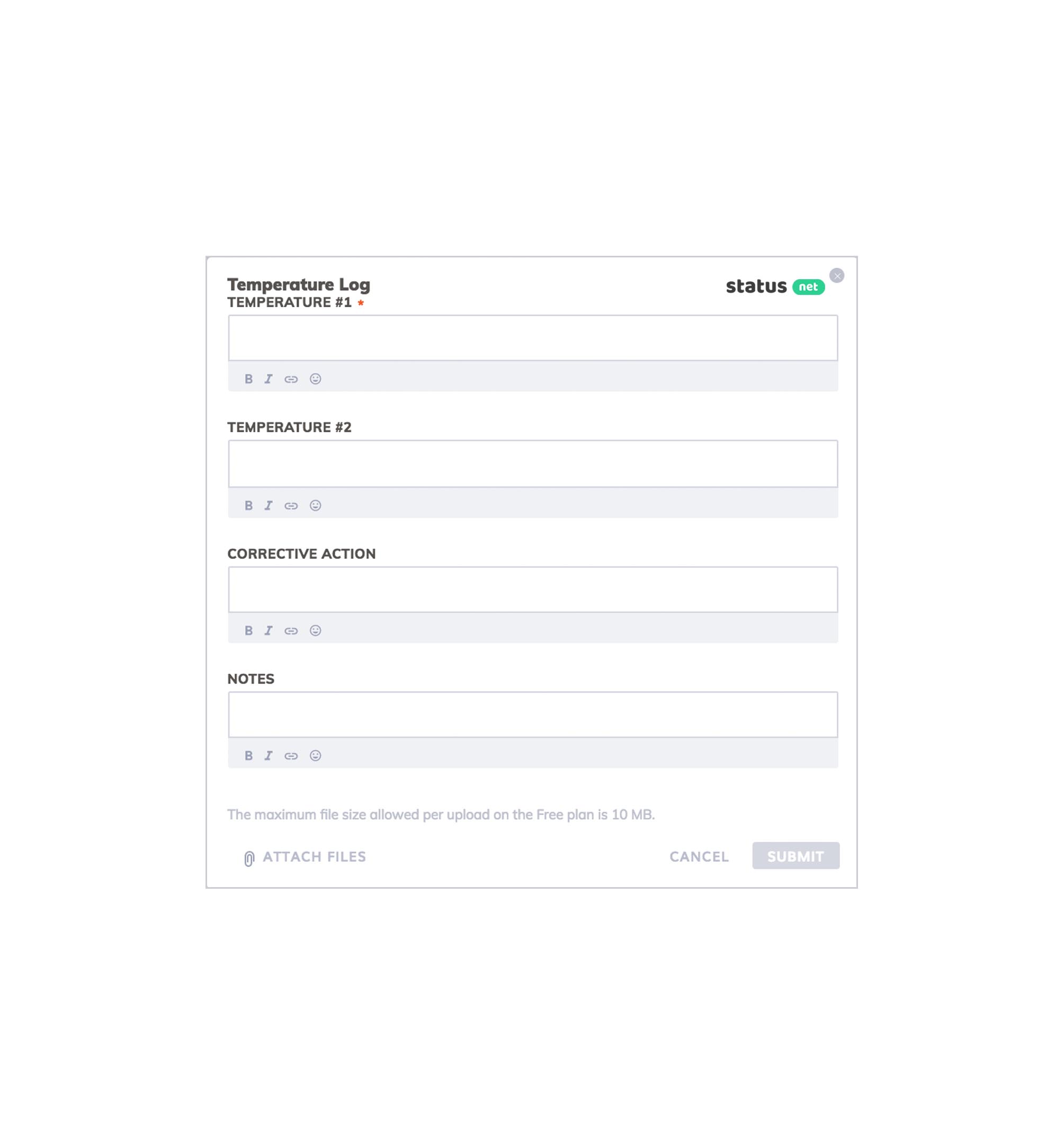

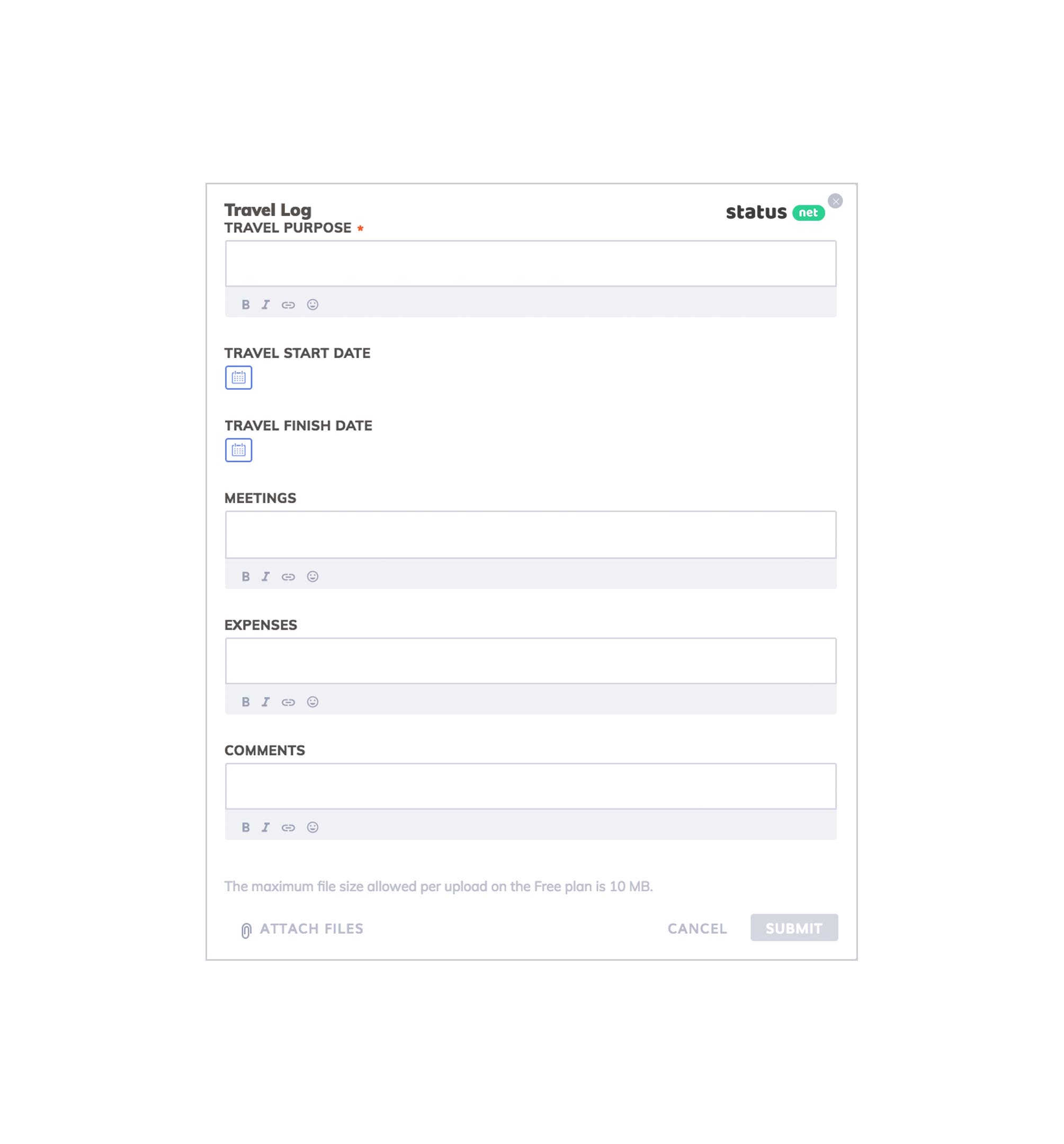

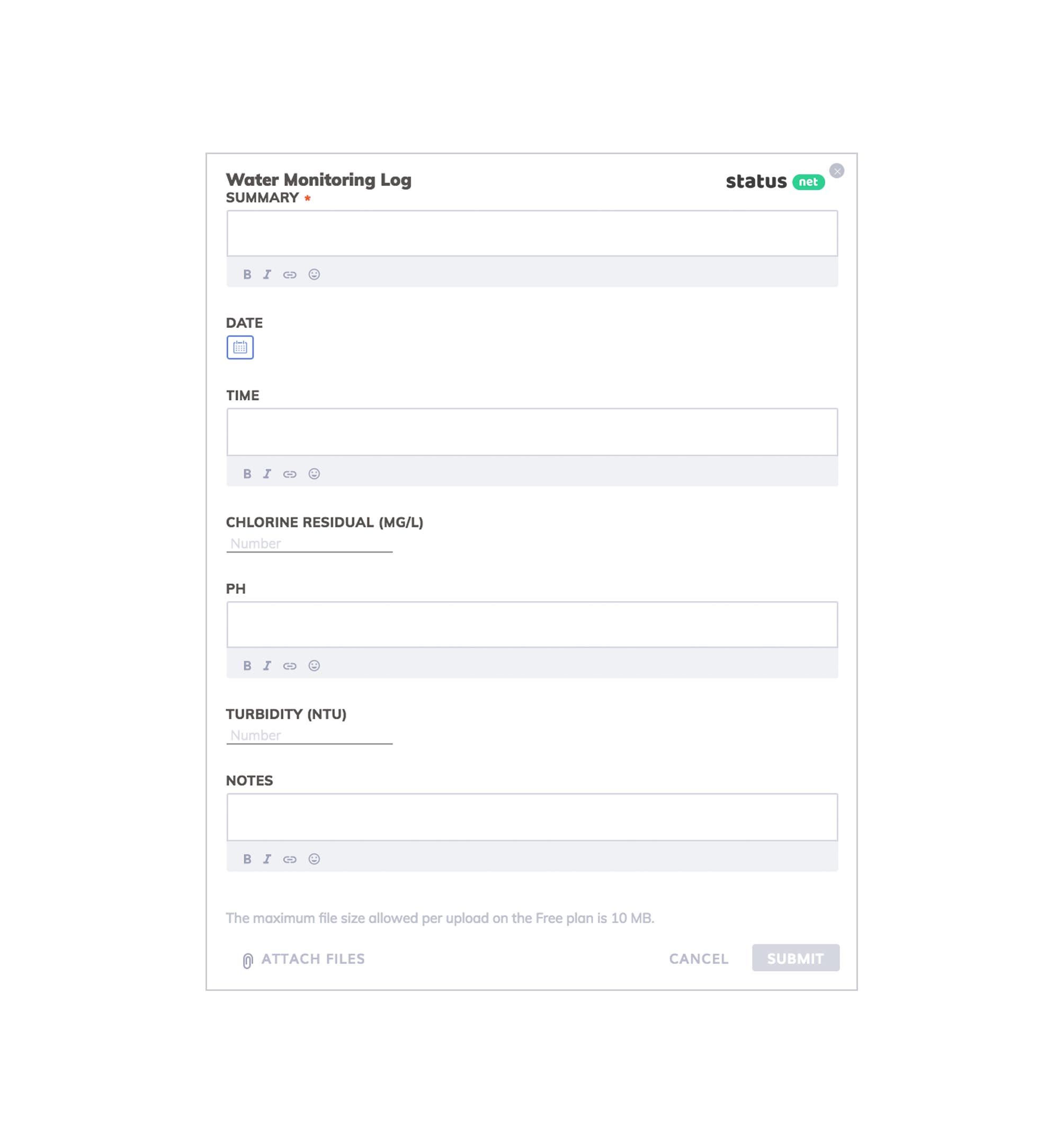

Sample Template of an Equipment Maintenance Log

An excellent sample would look like this: