- What Is 5S Lean? Part 1

- The Benefits of 5S Part 2

- 5S Audit Best Practices Part 3

- 5S Audit Free Sample Form Template Part 4

In order to improve operations, business organizations adopt various methodologies such as 5S Lean, 6S Lean, Just in time (JIT) production, six sigma initiatives, and cellular manufacturing.

The 5S initiative finds its origin in Japan as it was being used by the Toyota Motor Company. The system produces results by eliminating the waste that accompanies the production process.

Part 1

What Is 5S Lean?

5S Lean a system that is widely applied by the business organizations to organize the work for higher efficiency and safety within the organization. Every organization requires having the best way of ordering equipment and focusing on ensuring that everything is put in its rightful place. Therefore, this system was designed to answer that need.

During the discovery of this approach, it was originally communicated in Japanese. However, when embraced worldwide, those Japanese terms were translated to English. Below are the original Japanese words as well as their translation to English respectively:

- Seiri – Sort

- Seiton – Set in Order

- Seiso – Shine

- Seiketsu – Standardize

- Shitsuke – Sustain

The organization breaks its operations into modules, and each module is assigned a team of specialists. By the implementation of the 5S method, it means total cleaning up and the organization of the workplace in its existing configuration. The lean methods motivate the employees to improve their working environment and reducing wastage. This method leads to the organization of tools and materials since they are labeled and stored in color-coded locations.

When the company applies this method, the methodology becomes helpful in removing the items that aren’t needed anymore (sort), keep the items in an organized manner to promote efficiency (Straighten). Additionally, the area is cleaned to easily identify the faults (shine).

In order to avoid confusing the areas where the materials and equipped are stored, color coding and labels are applied (standardize). Lastly, all these practices need to be maintained over a period of time. Therefore, the term “sustain” comes into play.

Part 2

What Are the Benefits of 5S?

Is this system really beneficial in any way? Absolutely yes. In addition to the few mentioned advantages of the 5S system here is an in-depth discussion of the advantages of implementing the system.

-

Improved Efficiency

The primary goal of the 5S is to eliminate the items that are not being used. By so doing, the items needed are easily identified. Often the unnecessary tools, scrap materials, as well as unused stock, are found everywhere. The organization, labeling and the keeping close those items that are needed leads to time management and therefore more productivity. By keeping the material and tools at accessible places reduces fatigue and more efficiency in the workplace.

-

Reduced Costs

By freeing up the environment, enough work space is realized. This has a positive impact in reducing the overall costs that are incurred in rental, cleaning and maintaining that space.

-

Improved Maintenance and Less Down Time

Cleanliness is essential in a workplace. This comprises the cleaning of the machines, the equipment, and tools. By so doing, it becomes easy to detect the faulty and problems such as oil leaks. In this case, maintenance is addressed easily before the problem could be worse.

-

Improved Safety

There are many ways in which the 5S collectively leads promotes safety within a working environment. It includes the following:

✔ Quick cleaning of the spills eliminates the potential risks of falling and slippage.

✔ Having the tools and materials needed close reduces the frequent movements that could pose risks to injury.

✔ Standardization eliminates unsafe practices.

-

Commitment to Job

The productivity of the employees is directly proportional to the way management treats them. Whenever the employees see that they are valued and cared for their morale is improved. By providing clean and organized workplace improves their attitudes. Therefore, this should be a secret to every employer. At times, providing clean, organized and quality standards may be the motivation that the employees could be lacking to increase their productivity.

Part 3

Best Practices

In order to fully implement the 5s system, it is imperative to know what to do. This includes the breakdown of the activities under each ‘S’. Here are the activities that are under 5S:

1. Sort

It involves identifying the necessary and eliminating the unnecessary. This is achieved by:

- Clearing unwanted items from an area

- Tagging of the items that are not needed

- Define a special area for the items that are difficult to classify

2. Straighten

This involves keeping the needed item in an accessible place to reduce time wastage. The activities under the roof of this ‘S’ include the following:

- Identification and allocation of the materials that are needed for work

- Storing them in fixed places and quantities

3. Shine

Eliminate the garbage and dirt for the easier identification of an area. This involves the following:

- Identify the source of dirt and deal with it

- Setting up workstations in a few places

- Storing the tools after cleaning them

- Proper lighting of the rooms to easily see dirt and dust

4. Standardize

Ensuring some level of stands for neatness and clean workplace

- Have labels on items and rooms by using color codes

5. Sustain

This is practicing the behaviors to establish the system over a long period of time. This includes the following:

- Commitment of the leaders to the responsibilities

- Sticking to the rules

- Corporate participation in developing the habits for the organization

- Periodic reviews

Part 4

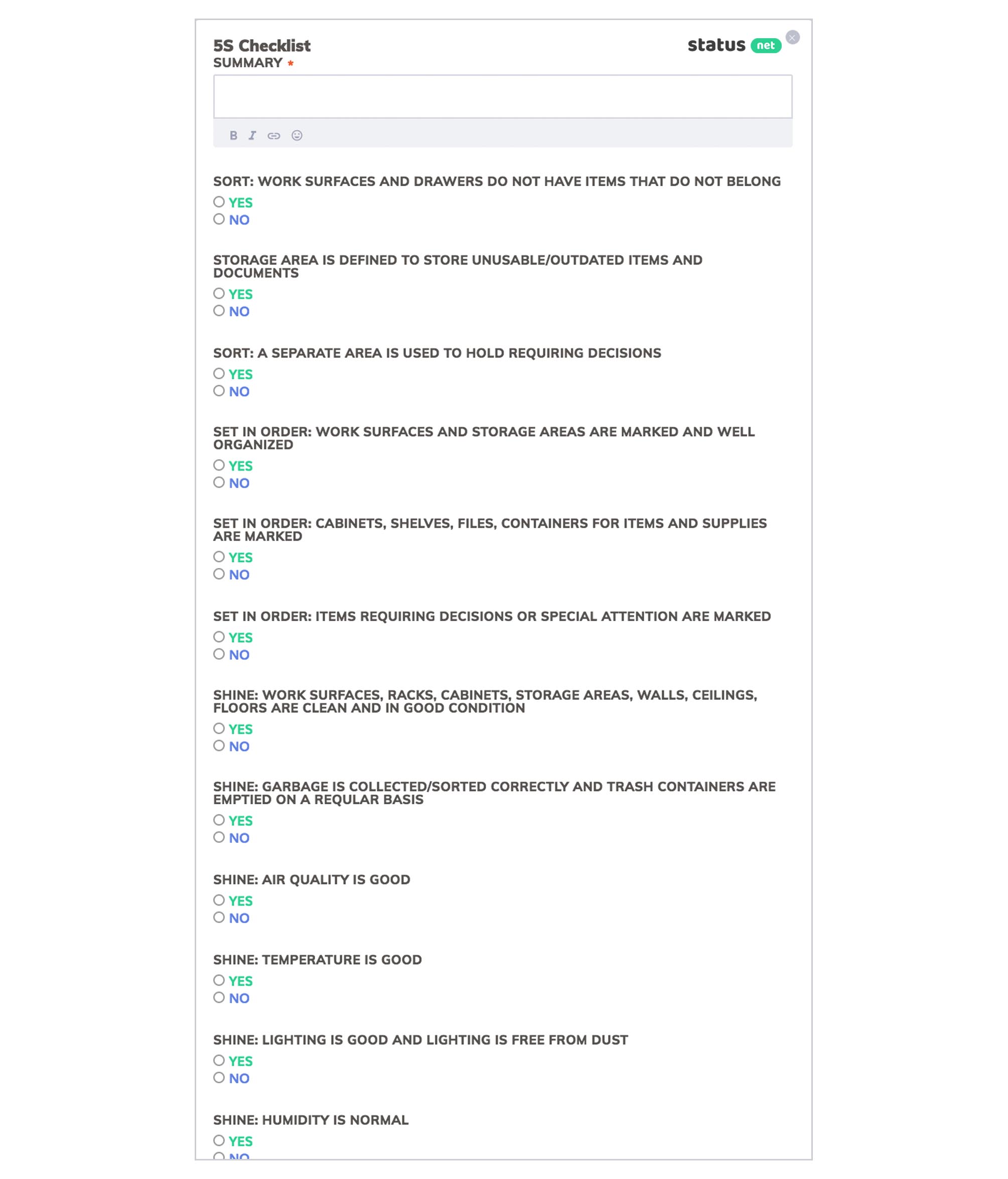

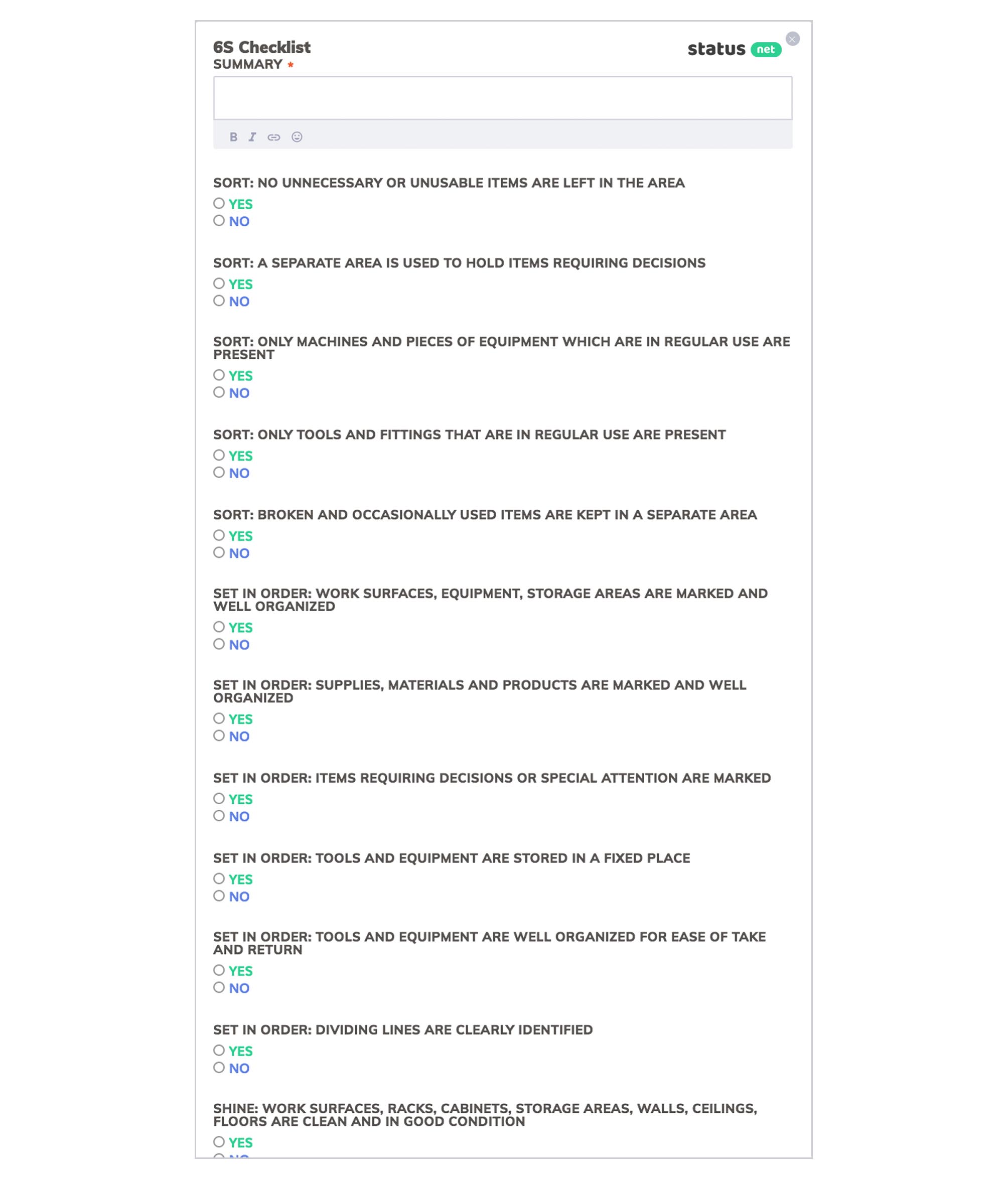

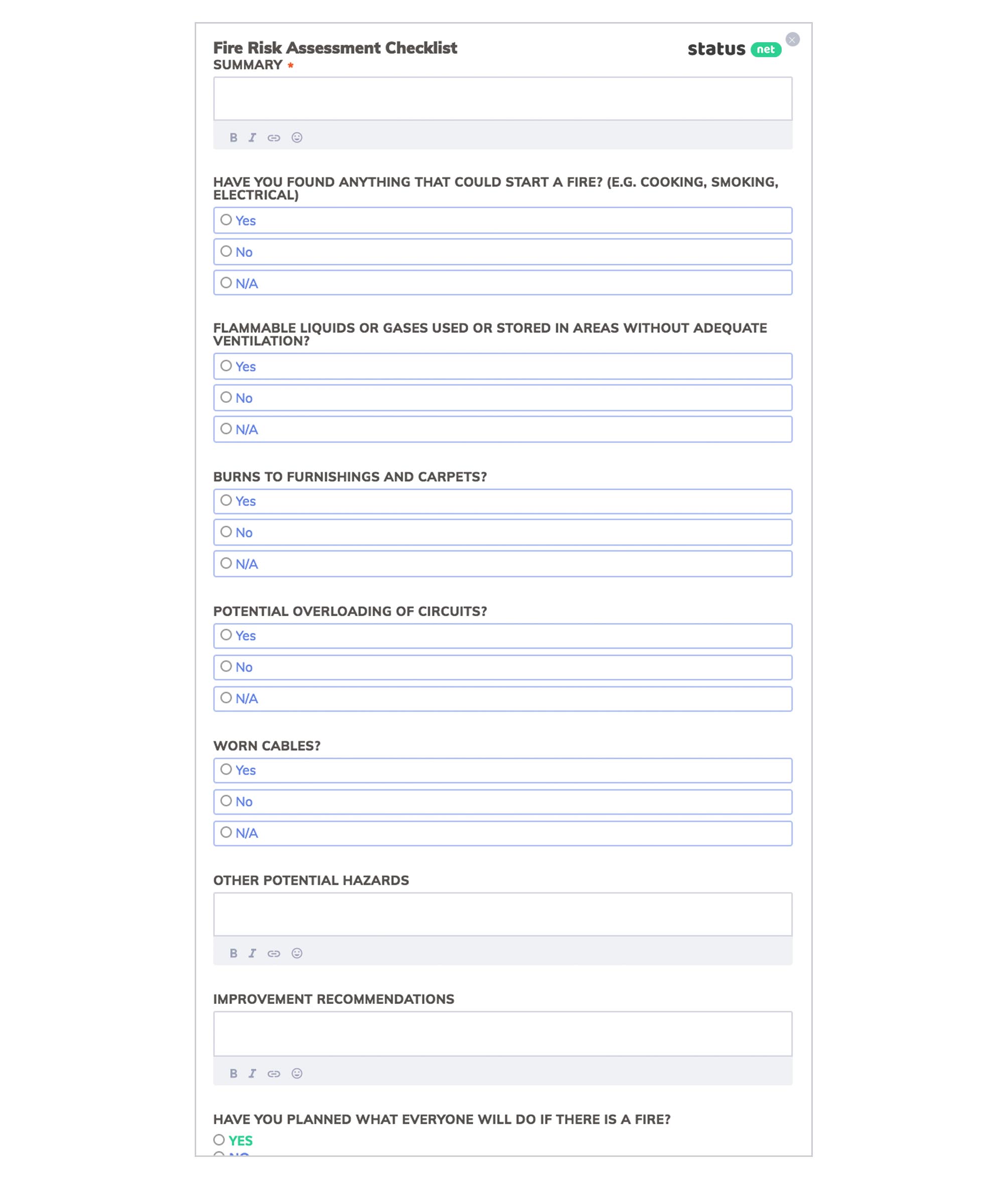

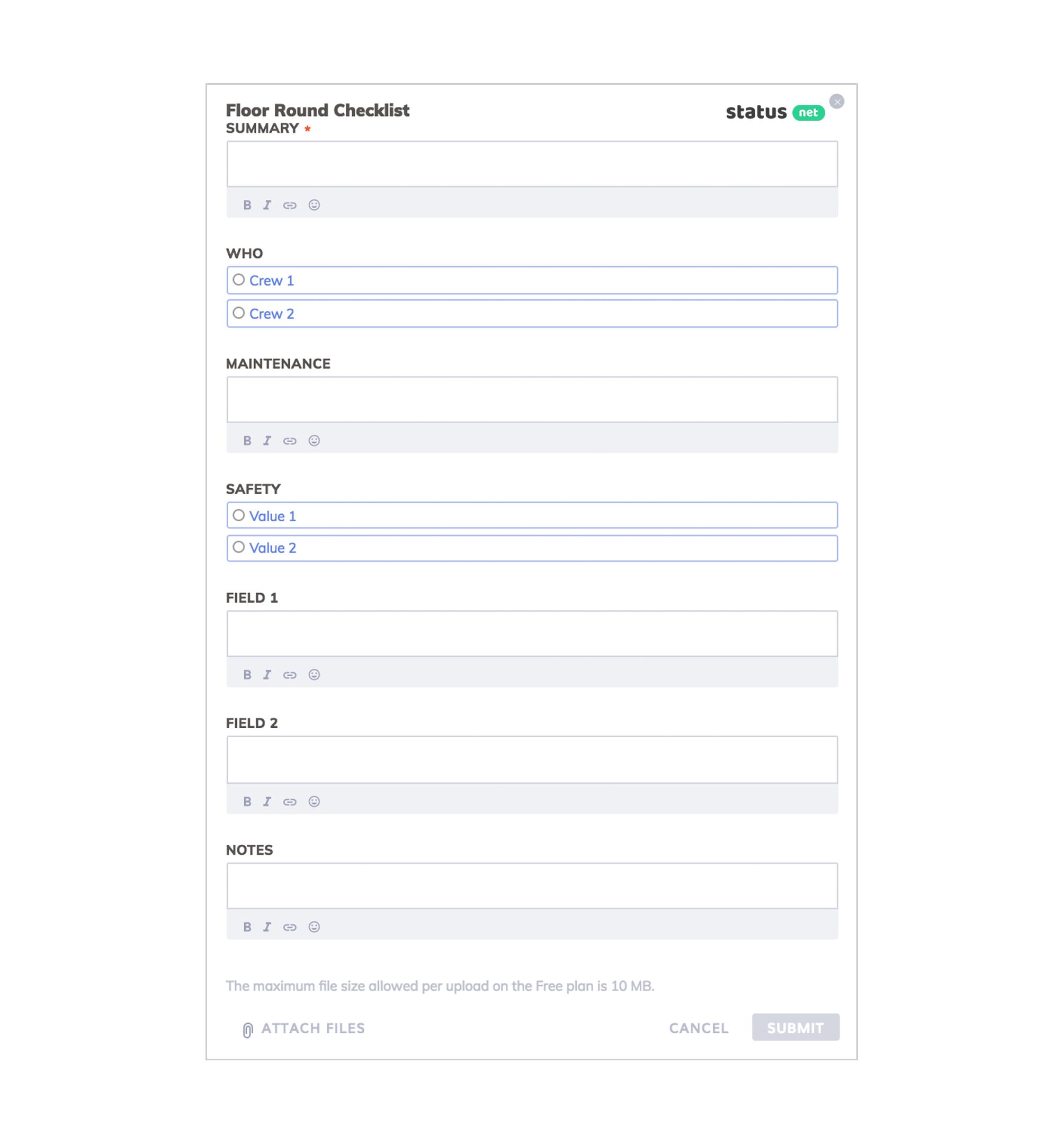

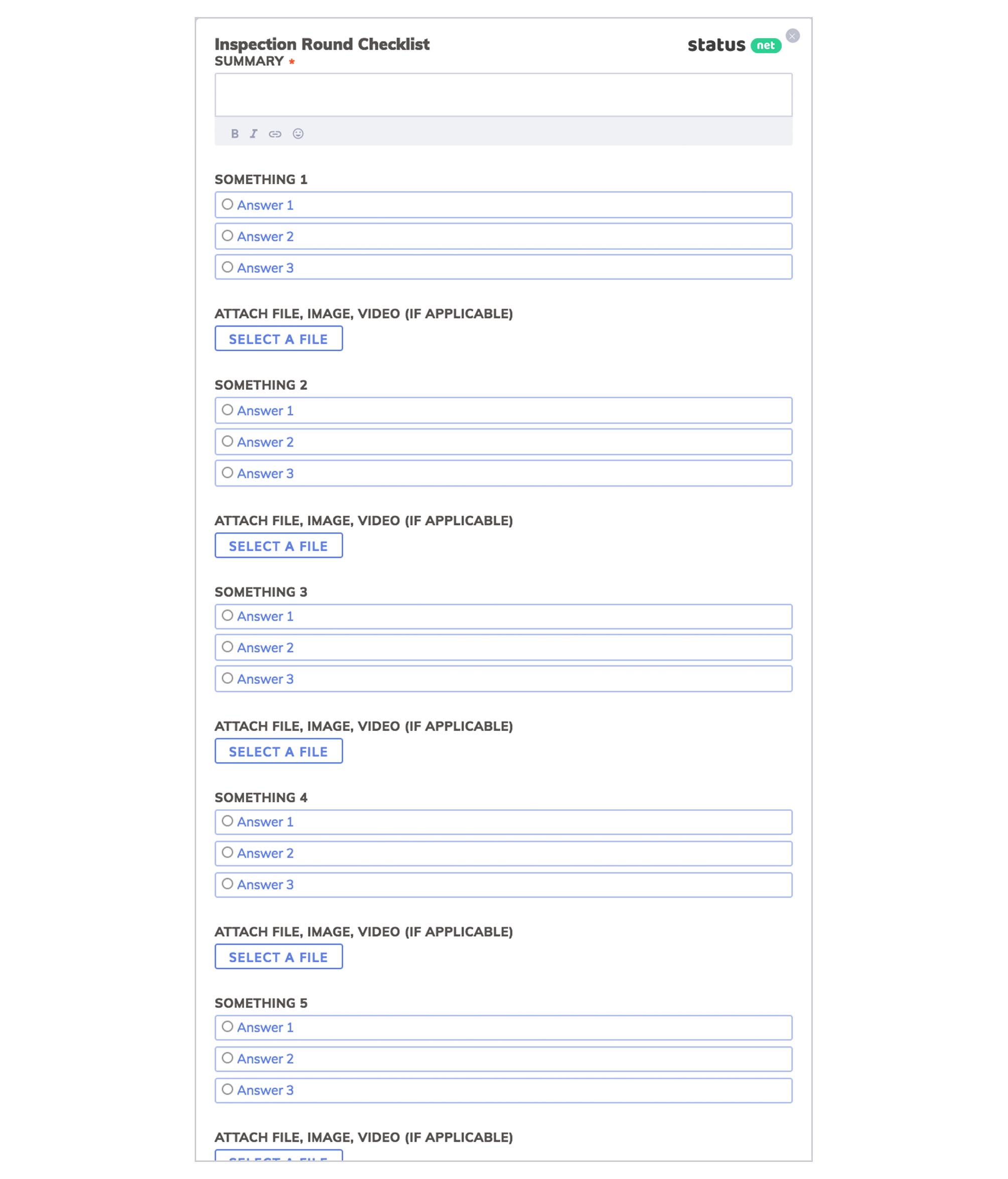

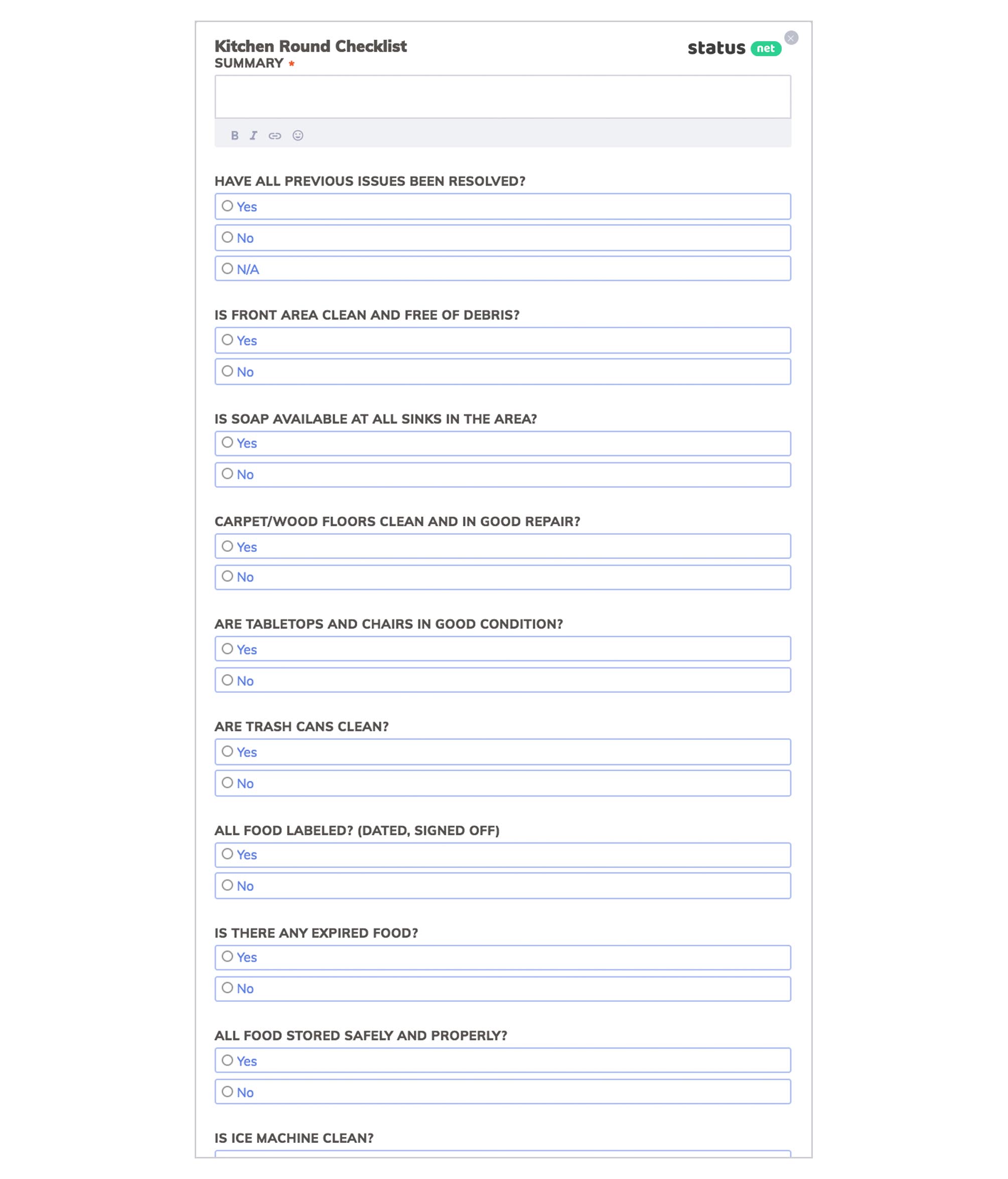

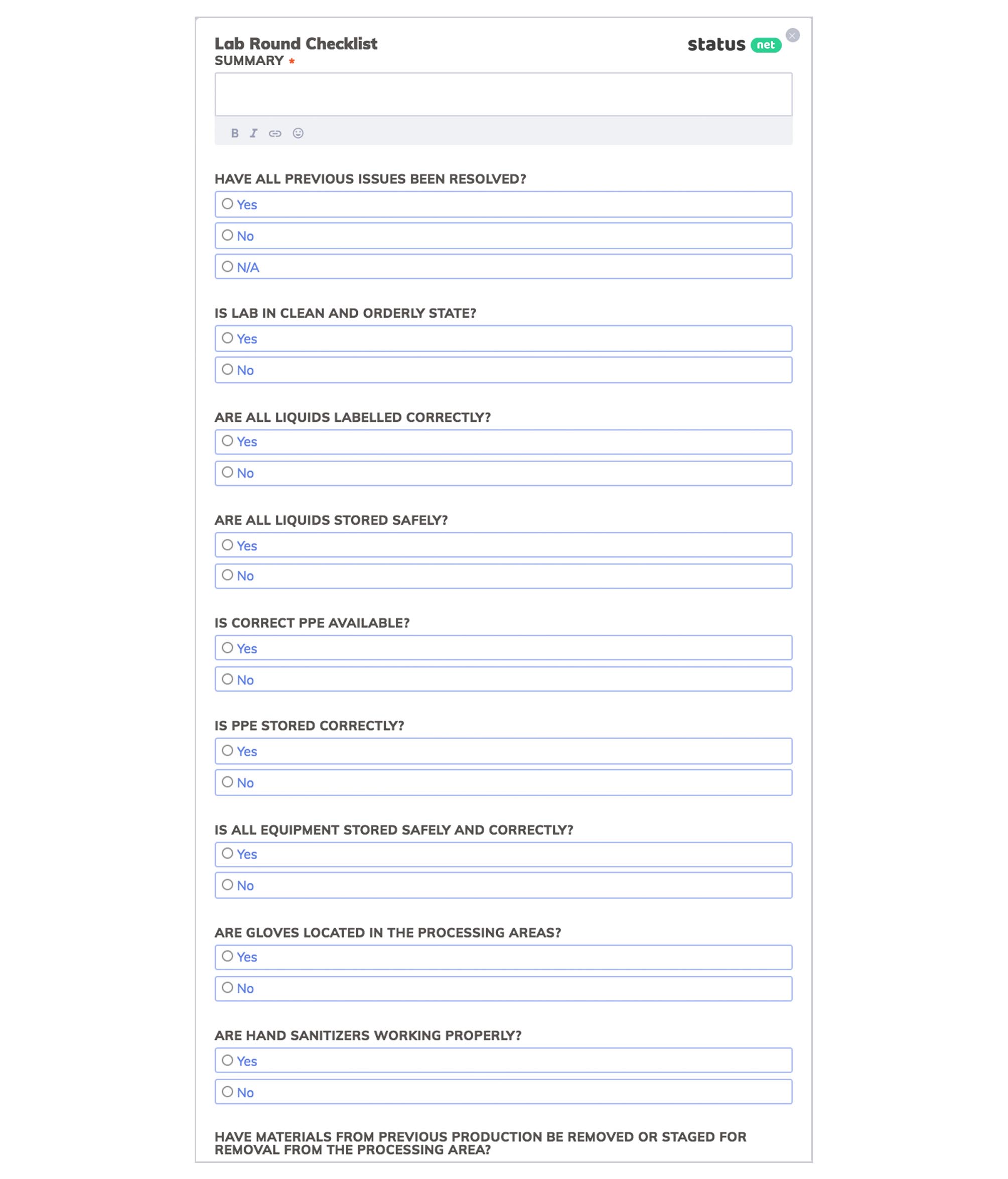

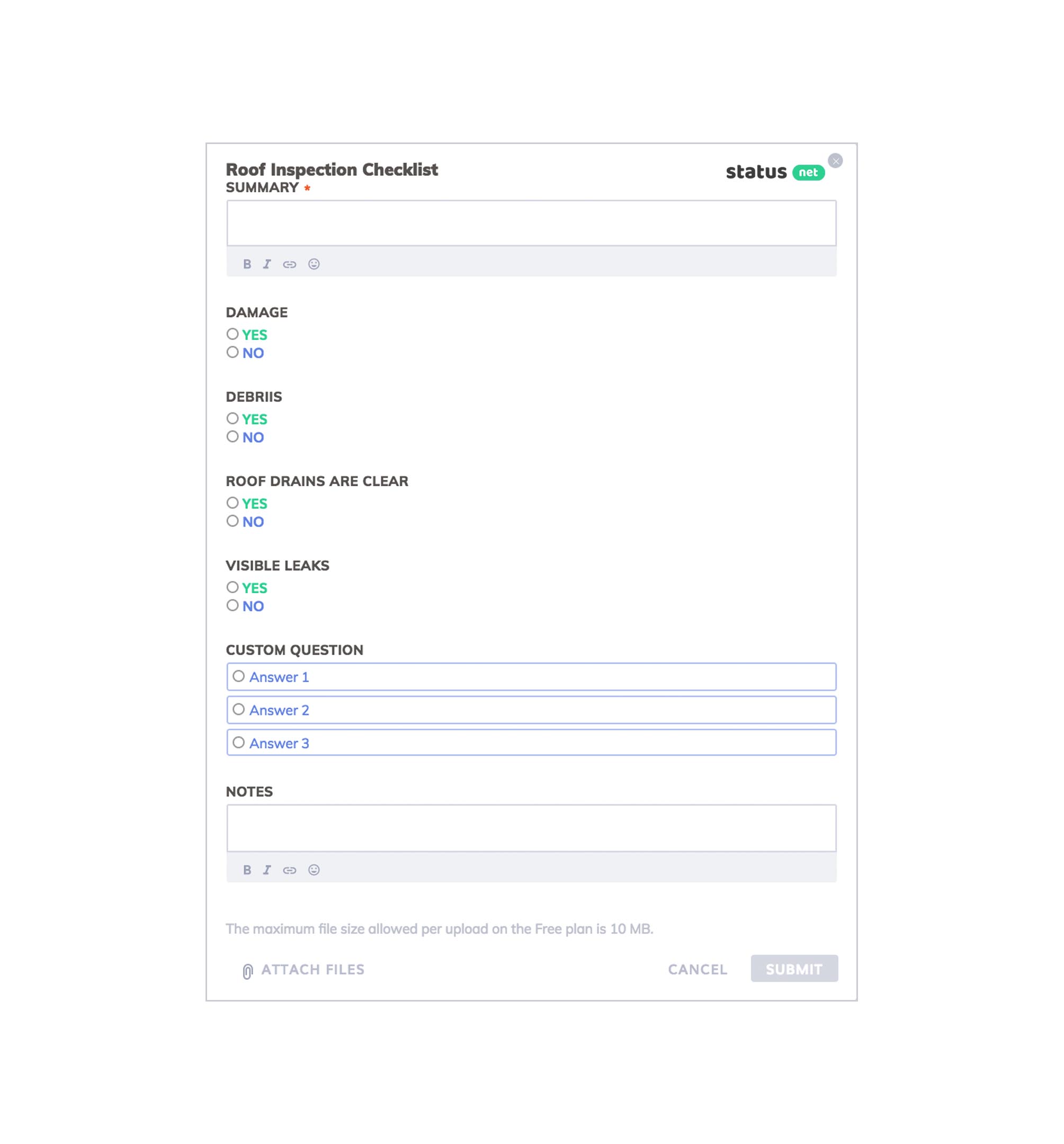

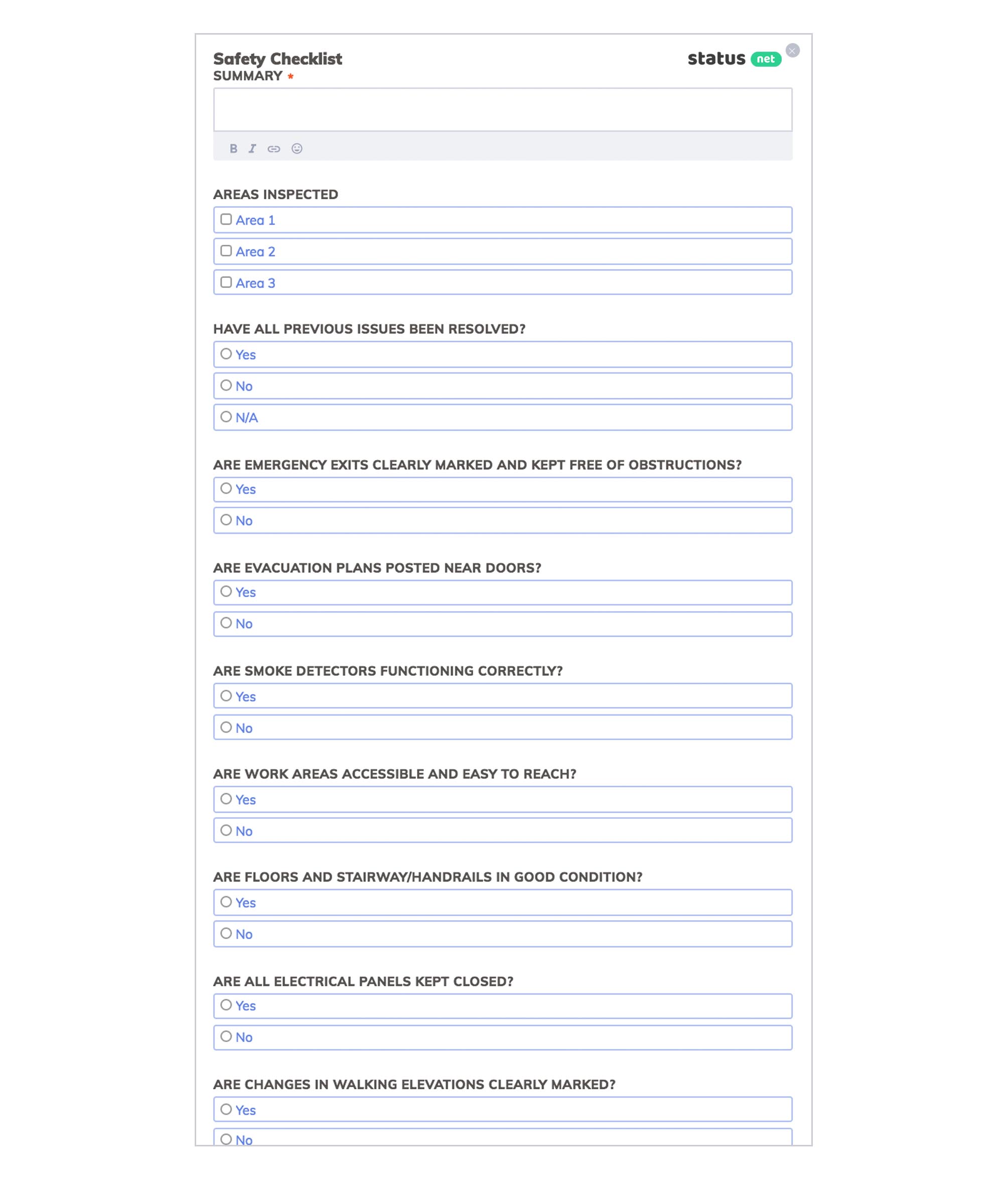

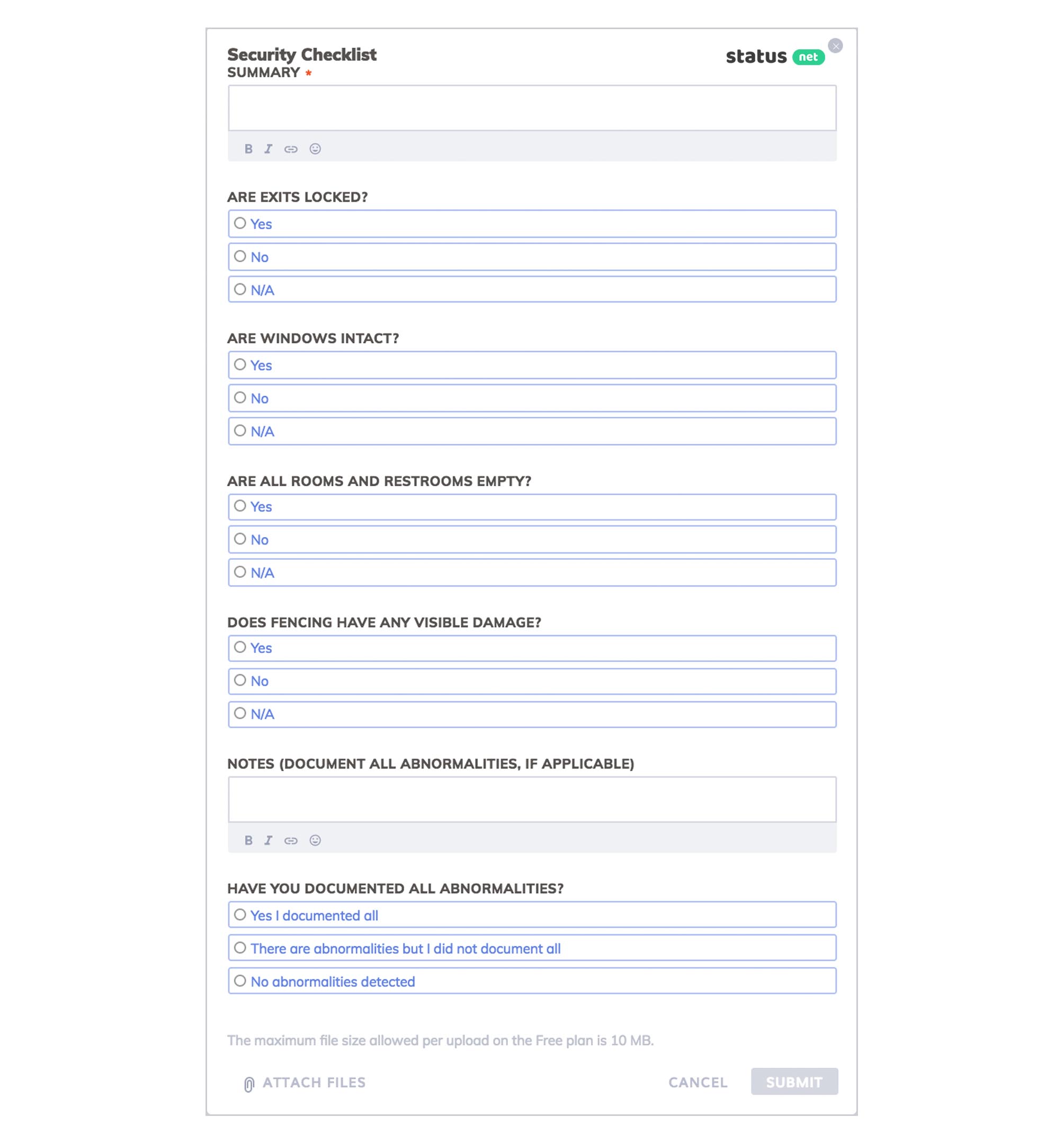

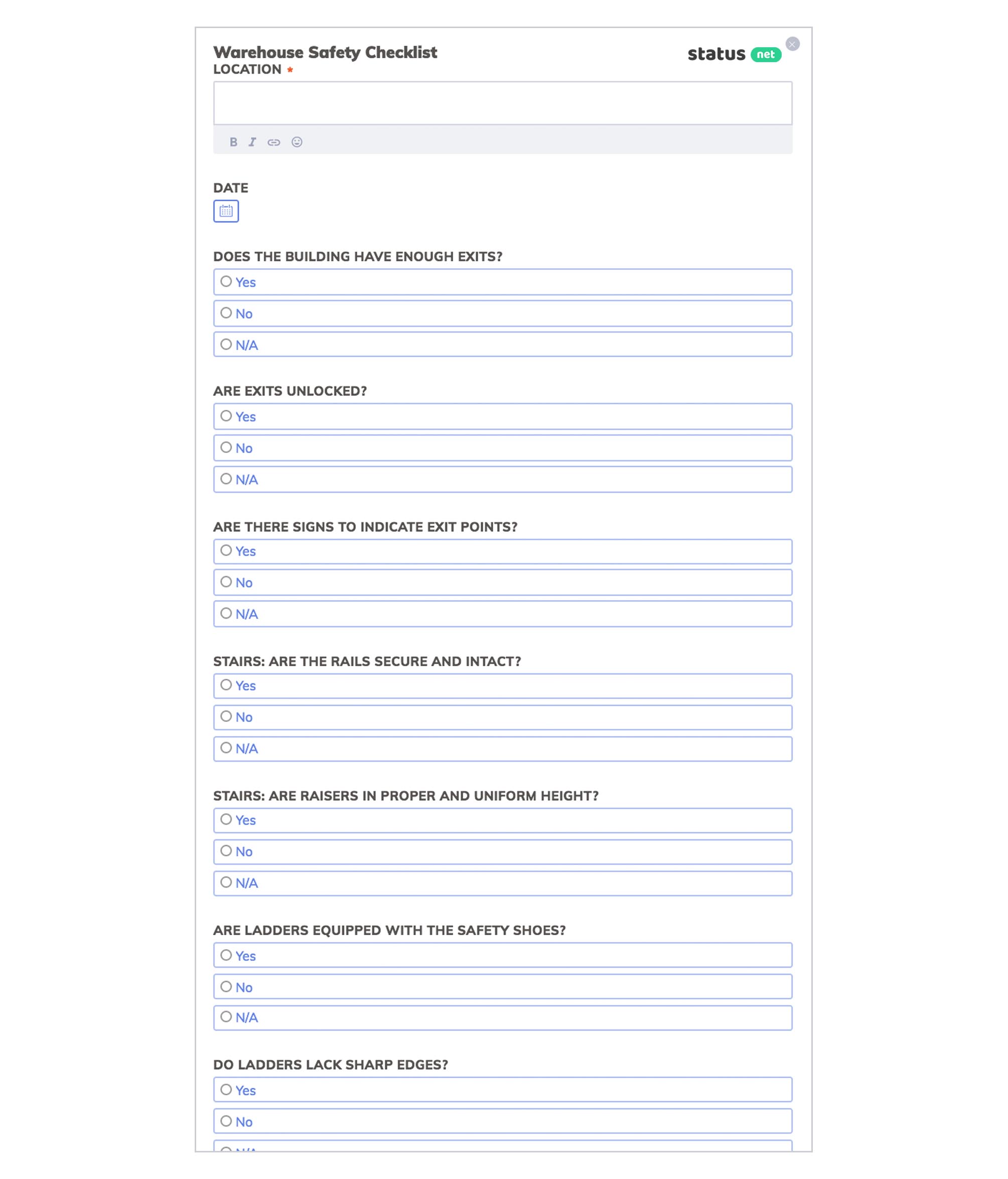

Sample of An Excellent 5s Lean Form

In order for the 5S to be implemented easily, business organizations come up with an audit form. This is a checklist that consists of the 5S in a column and checking of activities under each ‘S’ is done on the other columns. Below is an example of the first 1st ‘S’ (Sort) audit form:

5S Audit Form – 1st ‘S’, Sort Phase

Audit Questions Yes/No How to Improve

Are paths clear and marked?

Are the necessary tools available?

Any unnecessary items available?

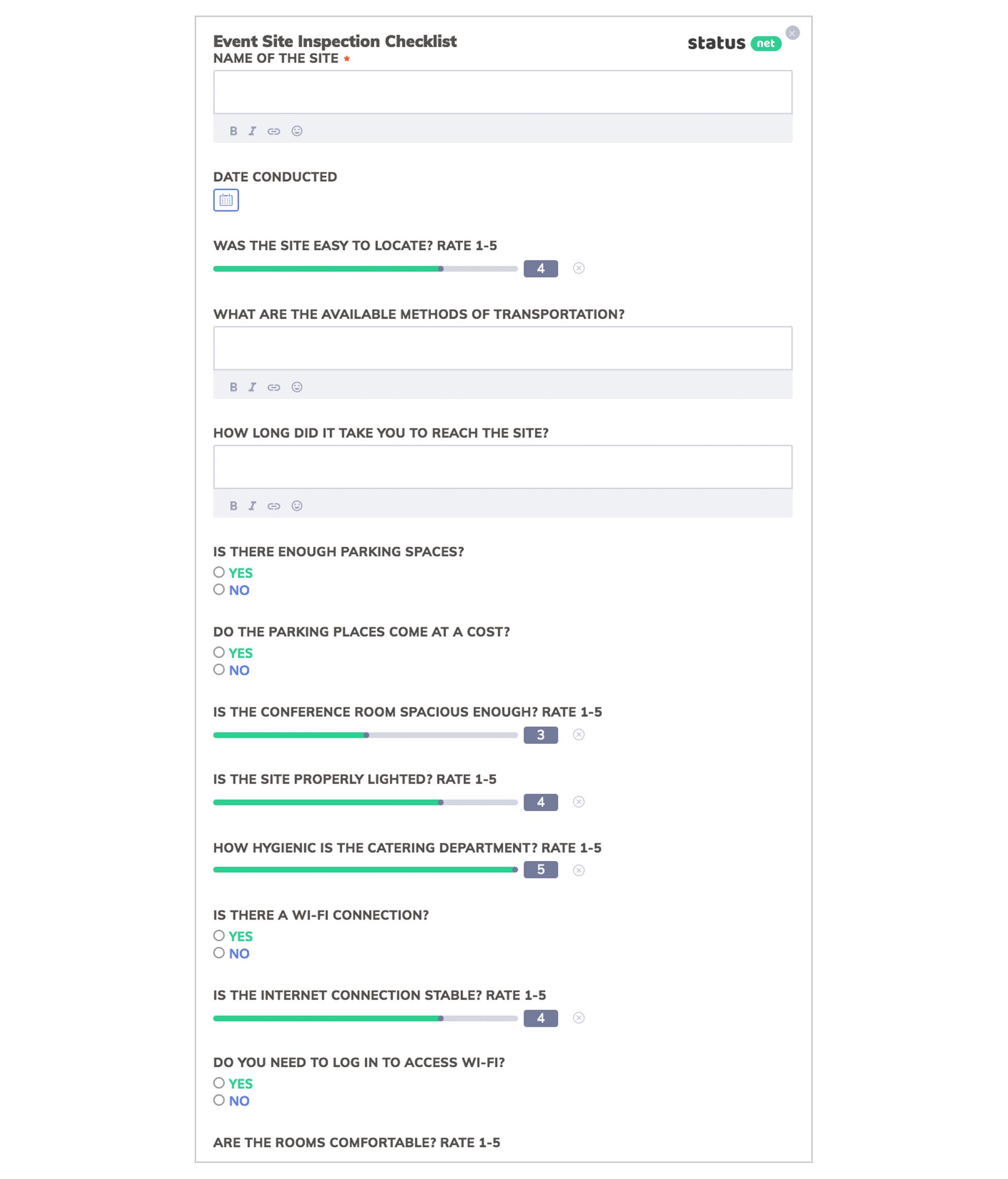

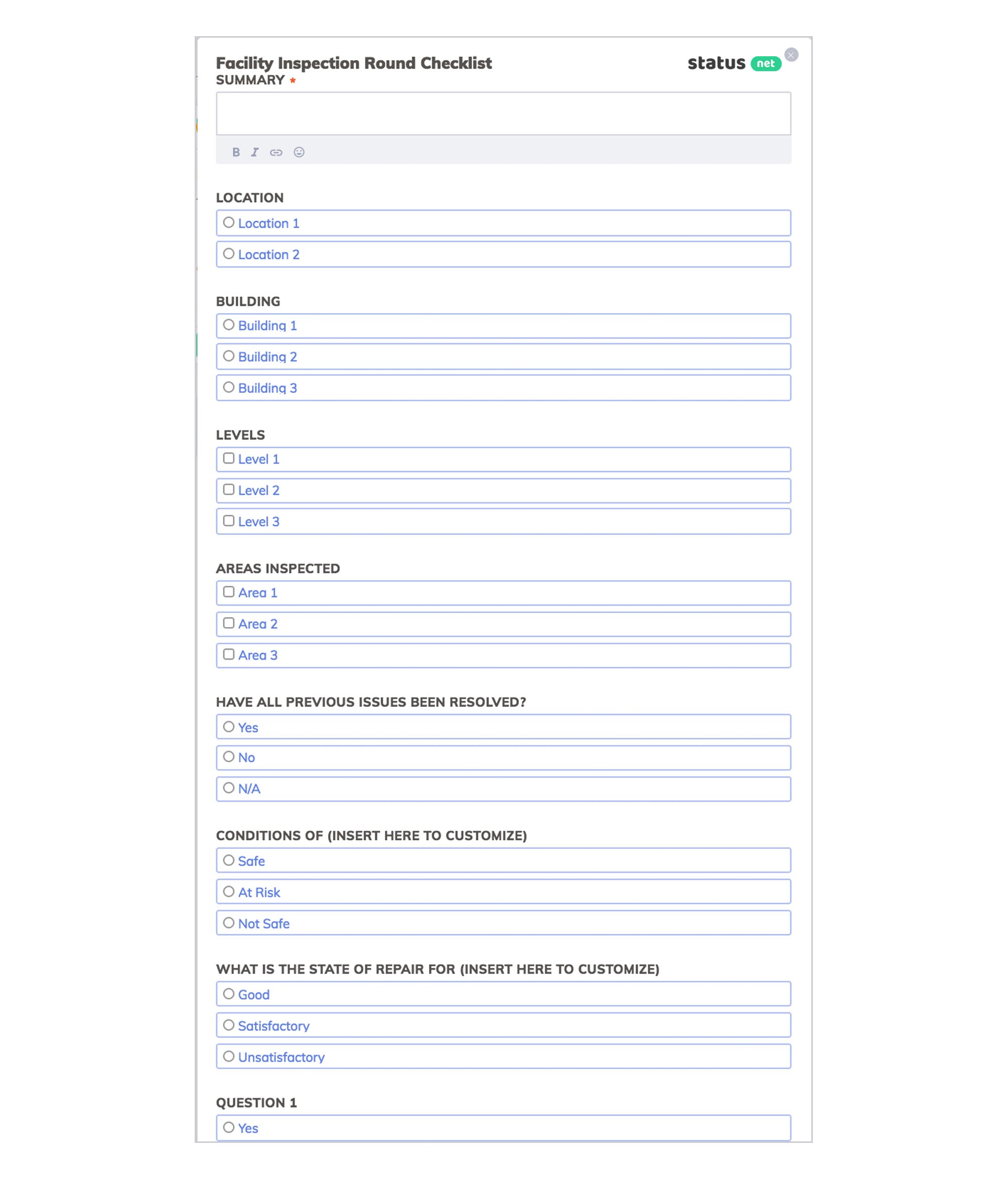

Since each company needs to have a smooth flow of activities with high productivity, 5S becomes a mandatory system to help achieve this. This is the most cost-effective technique. By implementing the 5S lean technique, the organization is guaranteed cleanliness, organization and time-saving in a workplace.Check the form below to see how a perfect 5s audit form should look like: