To keep repair workflows flawless and meticulous, futuristic companies are turning to simple but exceptionally reliable business documents called maintenance work orders. Providing a clear picture of how equipment maintenance works and seamlessly connecting your team of technicians, a work order is an essential document that accurately highlights the following:

- The employee responding to a checkup request

- A brief explanation of the entire undertaking in terms of urgency, among other aspects

- Deployable resources towards and time needed to successfully complete a given maintenance task

An ideal maintenance work order allows you to easily schedule repair requests, consequently reducing system breakdowns. However, without a clear understanding of the operational aspects of a maintenance work order, your checkup procedures may not be as smooth as they should be.

If you want to improve your knowledge of maintenance work orders and employ impressive equipment repair procedures, our comprehensive guide will help you. This article covers the most important topics regarding maintenance work orders, including:

- What Is a Maintenance Work Order Part 1

- Types of Maintenance Work Orders Part 2

- Benefits of Using Maintenance Work Orders Part 3

- Essential Components of a Maintenance Work Order Template Part 4

- Best Practices When Using Maintenance Work Orders Part 5

- Maintenance Work Order Template Part 6

Part 1

What Is a Maintenance Work Order?

A maintenance work order is a powerful business document that enhances the repair and maintenance operations of your organization’s assets. While this incredible tool can be either electronically or physically generated, the main objective of any maintenance work order is to provide deeper insights into your equipment checkup workflows.

This helps you schedule tasks and control the execution procedure, thus keeping you at the top of your game. Inclusive of a detailed outline of various aspects of a maintenance procedure, this comprehensive document ensures timely initiation and meticulous management of your company’s asset repair and care undertakings.

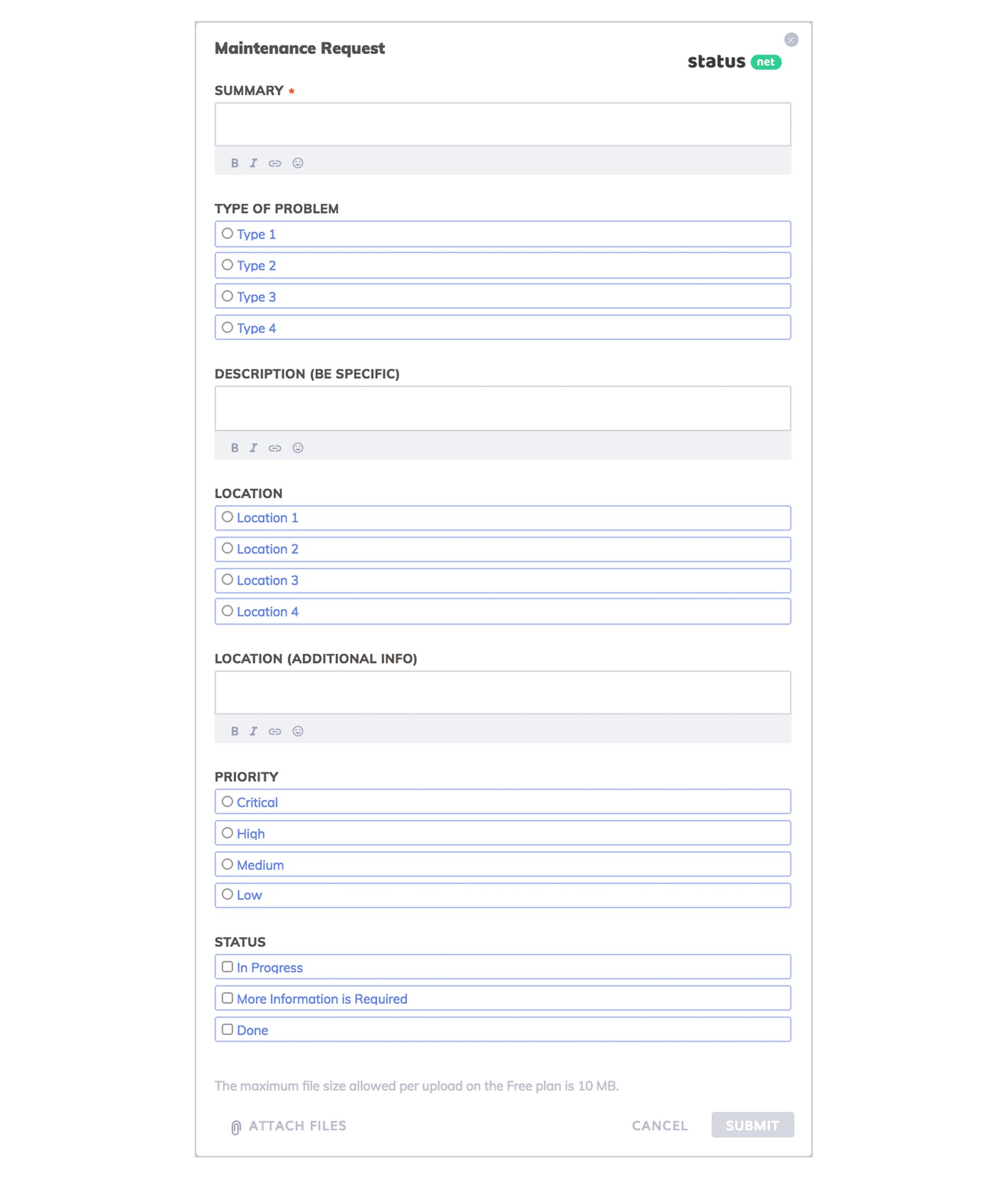

ProsperForms – work order software. Get Started Now

Part 2

Types of Maintenance Work Orders

While maintenance procedures vary across different scenarios (number of tools involved, level of professionalism needed, and deployable resources), there are two main types of maintenance work order:

-

Precautionary Repair Work Order

Most commonly applied in typical scenarios, precautionary work orders predominantly deal with the management of standard equipment checkup procedures. This approach features forest dates, schedules, procedures, and sometimes specialists who will be involved in the entire exercise.

-

Corrective Repair Work Order

This unique type of equipment maintenance is initiated as an auxiliary procedure in response to abrupt checkup requests. With corrective maintenance, there are no specific dates or schedules, as it does not adhere to the typical repair calendar.

Tip: Despite the slight variances in their application, corrective and precautionary maintenance work orders are equally important. An ideal maintenance system should incorporate both approaches.

Part 3

Benefits of Using Maintenance Work Orders

Maintenance work orders are remarkably vital business tools. Incorporating this equipment repair system improves your ability to oversee and seamlessly monitor what is going on across dozens of maintenance activities. This greatly boosts your decision-making ability, which consequently enhances allocation of resources and task prioritization.

This document gives your employees a channel to forward urgent repair requests. With a comprehensive list of all the equipment that requires checkup, your supervisors can identify the most critically affected machine and quickly schedule it for repair, thus avoiding further damage which could result in inflated maintenance costs.

Maintenance work orders create a collaboration channel between technicians and supervisors, consequently enhancing the authorization process. This streamlines your venture’s repair procedures. Additionally, this document provides dozens of benefits, including:

- Provides a detailed description of the problem

- Promotes prioritized scheduling of resources and tools depending on the urgency of the situation

- Offers your repair team insightful guidelines on how to execute a specific task

- Presents an effective documentation tool, thus promoting analysis of specific problems

- Enhances seamless monitoring of the maintenance process, thus ensuring accountability and application of the recommended procedures

ProsperForms – work order software. Get Started Now

Part 4

Essential Components of a Maintenance Work Order Template

A maintenance work order should be comprehensive, but it is also imperative to keep this document simple, straightforward, and concise.

Because an overly complex maintenance work order template may breed workflow failures and an extremely basic one may be inadequate for your venture’s lengthy requirements, you will need to strike a balance between comprehensiveness and simplicity.

To achieve this, all you need is a precise understanding of what information to include and what not to.

Some essential information that should feature in an ideal maintenance work order includes:

- Name of the employee requesting the maintenance work order

- Department that submitted the request

- Name of the manager approving the maintenance undertaking

- Details of the technical team allocated the job

- Exact date the work was authorized

- Expected completion date

- Brief description of the work and guidelines to follow when executing

- Name of the supervisor who examined the finished work

Part 5

Best Practices When Using Maintenance Work Orders

-

Conduct a Detailed System Analysis

First and foremost, to understand the exact measures and formulate reliable maintenance schedules, consider embarking on a detailed fact-finding mission. This allows you to gain deeper insights on the various aspects of your equipment.

Key features to establish when analyzing your tools include:

— Typical equipment interruption sequence

— Commonly affected parts in a specific tool -

Create a Checklist

Especially when conducting precautionary maintenance operations, it is essential to develop a comprehensive checklist. This highlights the parts of a machine that are most prone to malfunction. The checklist will provide your technicians with basic guidelines on where to investigate for possible problems.

Tip: To design an outstanding and reliable checklist, consider gaining insights from the manufacturer’s guidelines. -

Settle For the Most Cost-Effective Maintenance Procedure

While a technician has the opportunity to decide whether to replace or repair a faulty component of equipment, you should always take time, investigate the system breakdown, and decide on the best and most cost-effective way to solve the problem.

By doing so, you will avoid scheduling multiple maintenance procedures and save money. -

Make a Proper and Detailed Recording of Each Maintenance Procedure

The purpose of a maintenance work order is to rectify a faulty system and prevent impeding downtimes. Thus, properly documenting all procedures is imperative, as it provides future referencing.

ProsperForms – software for checklists and work orders. Get Started Now

Part 6

Maintenance Work Order Template

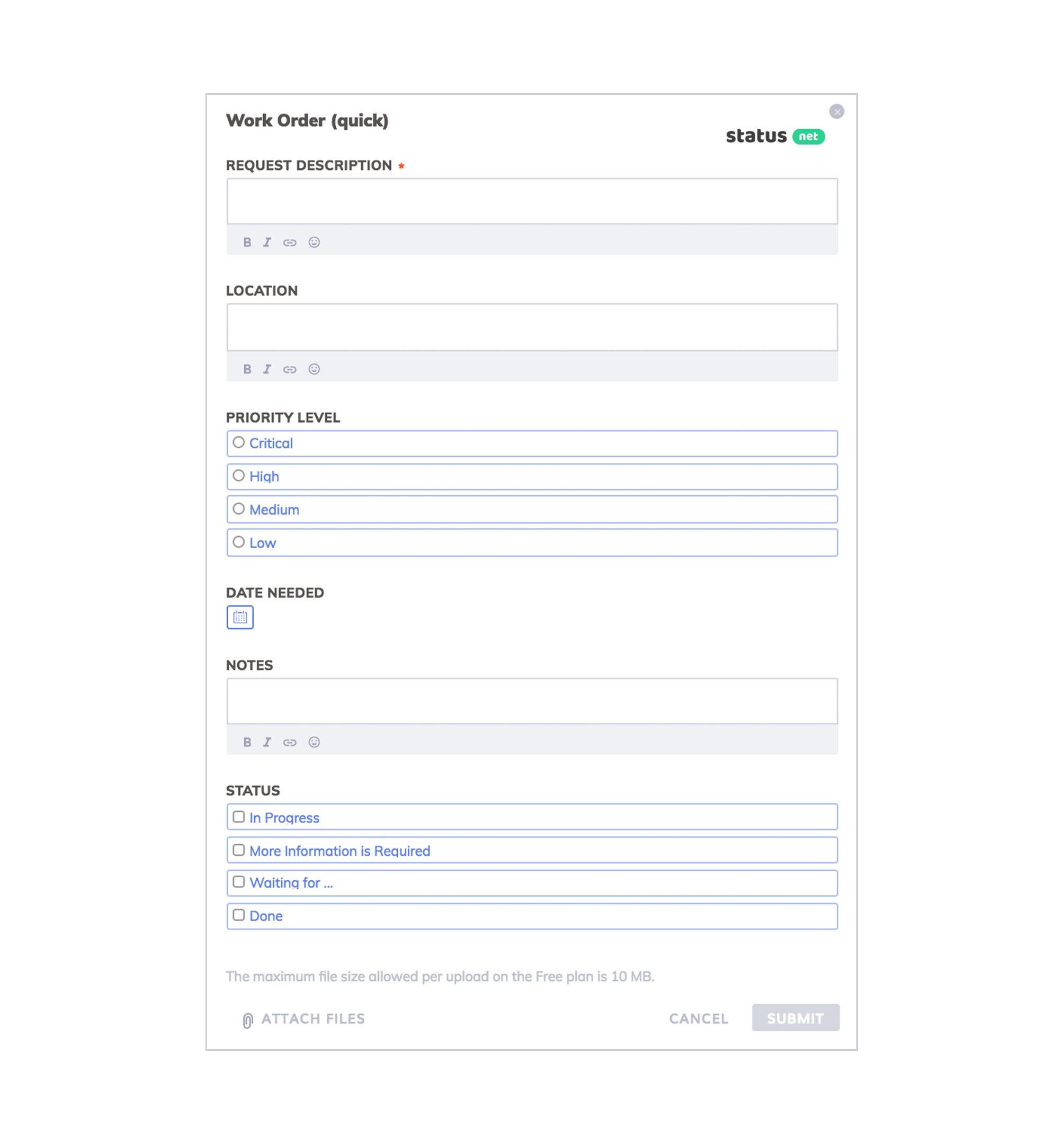

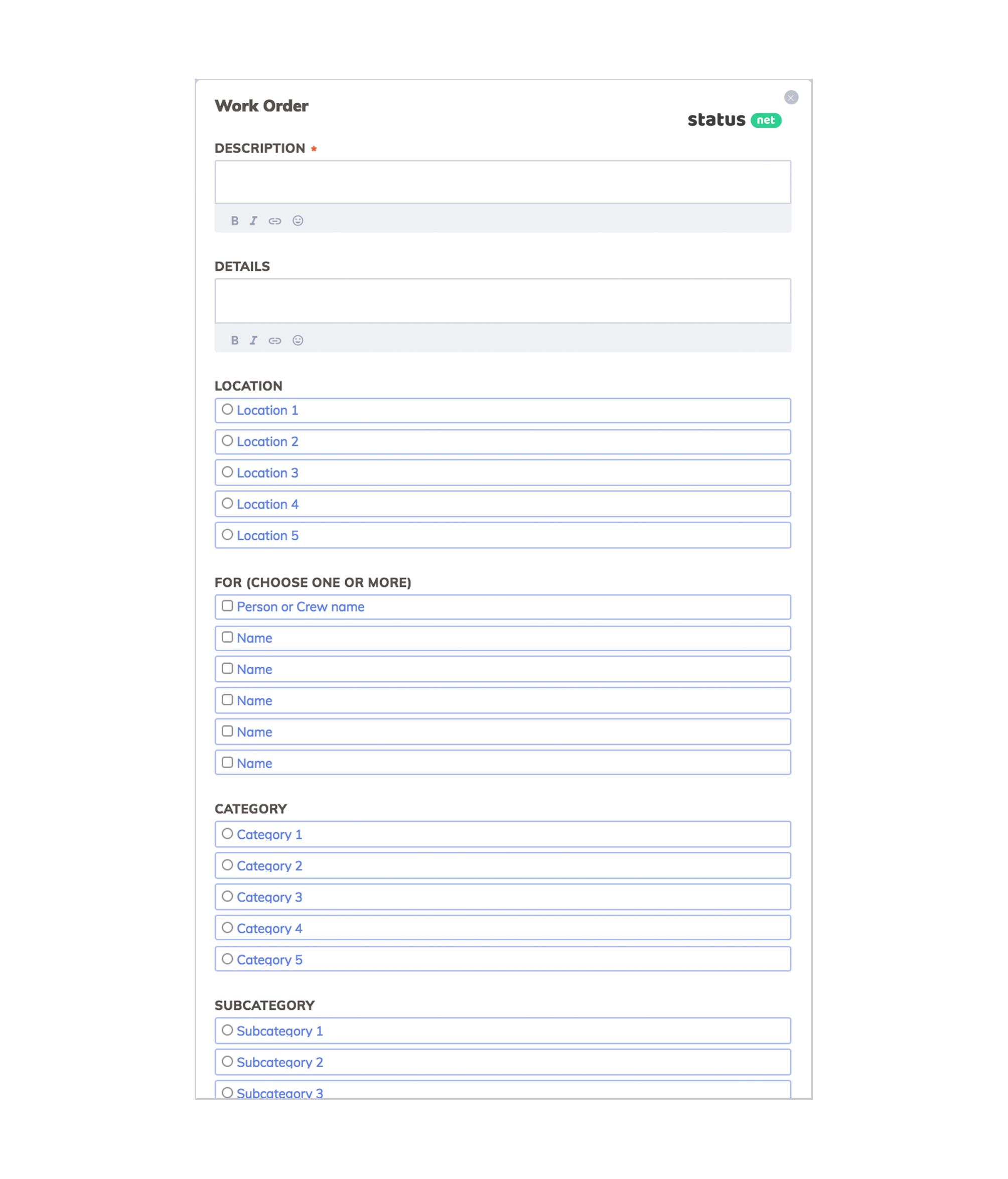

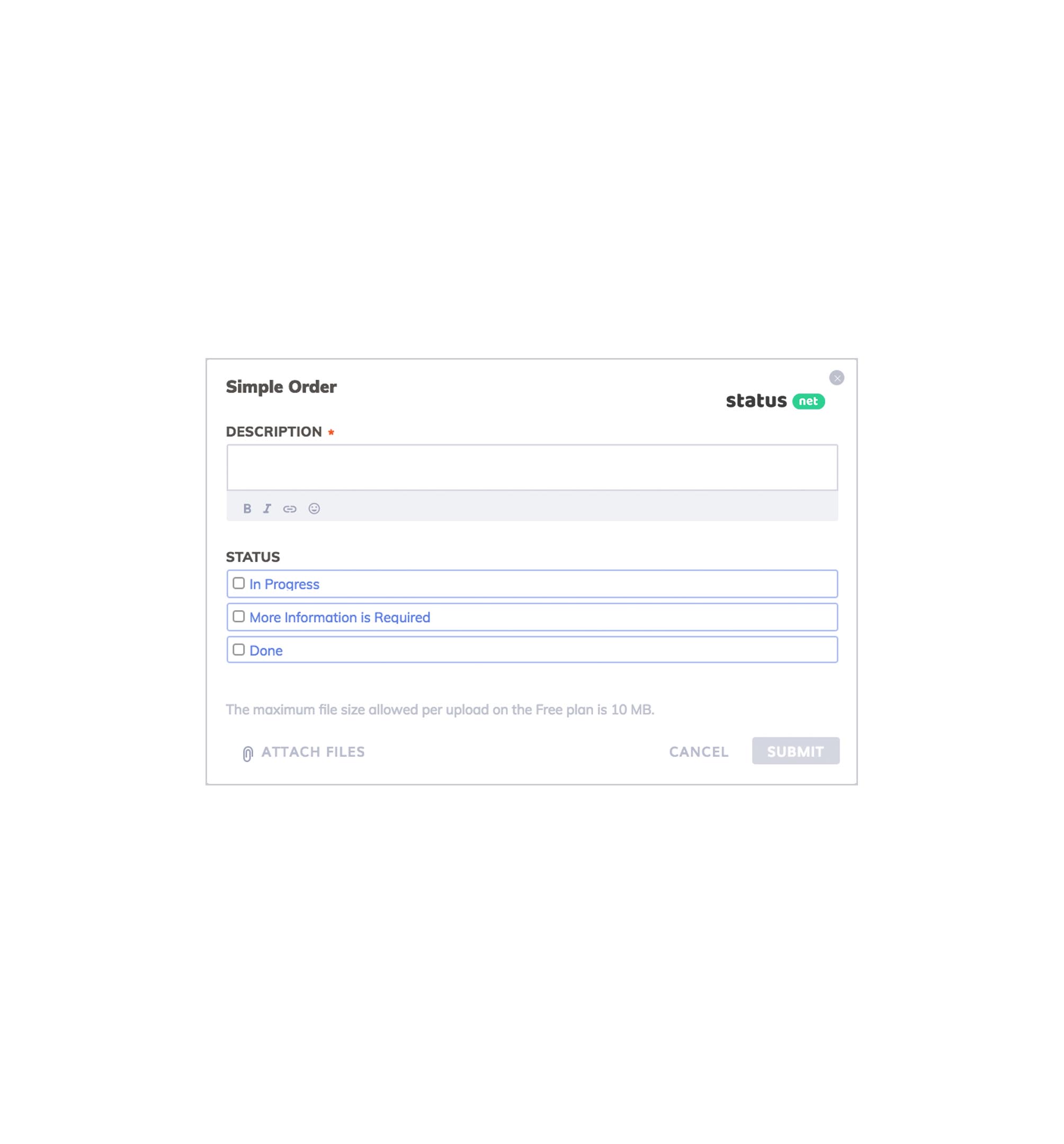

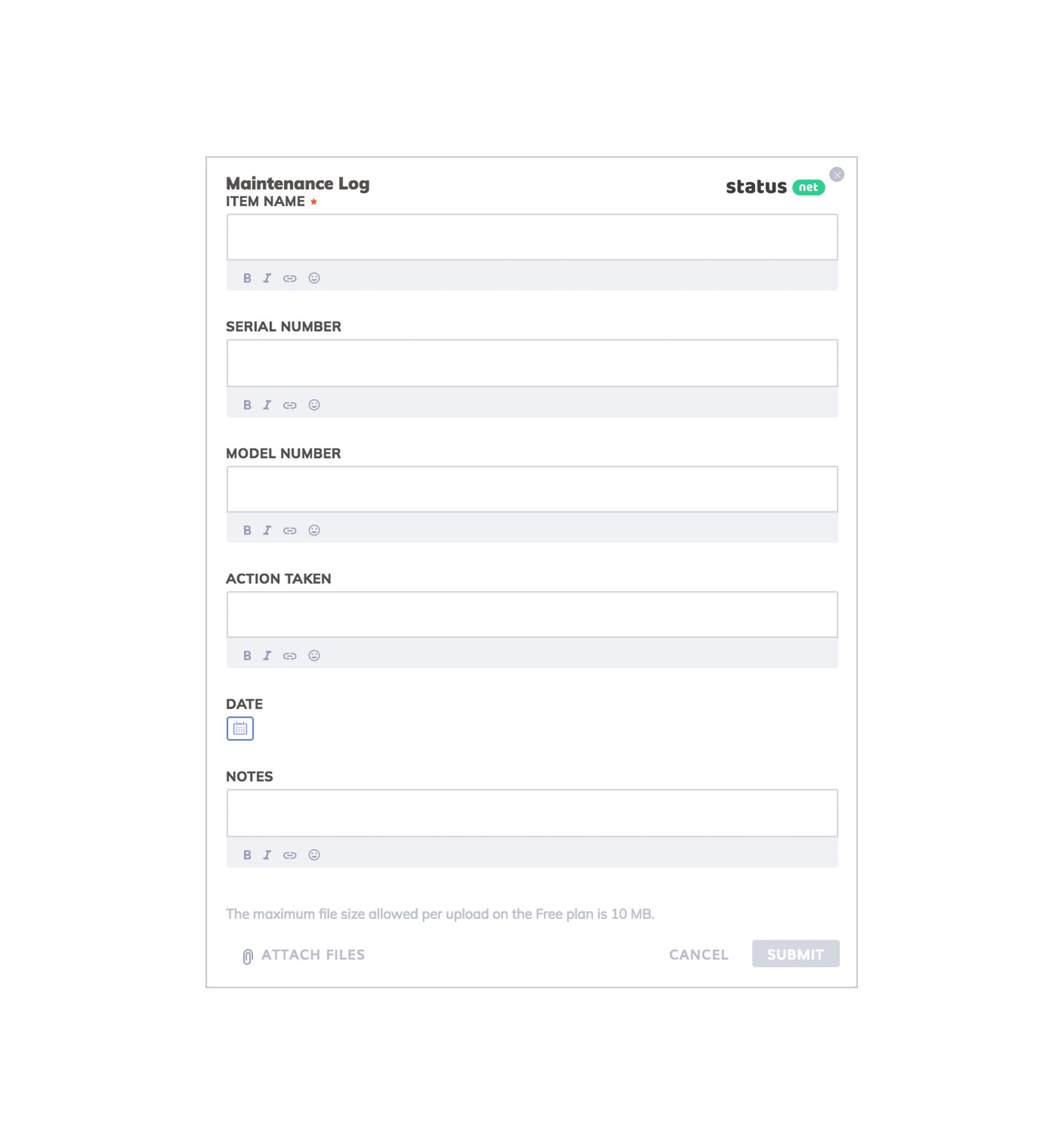

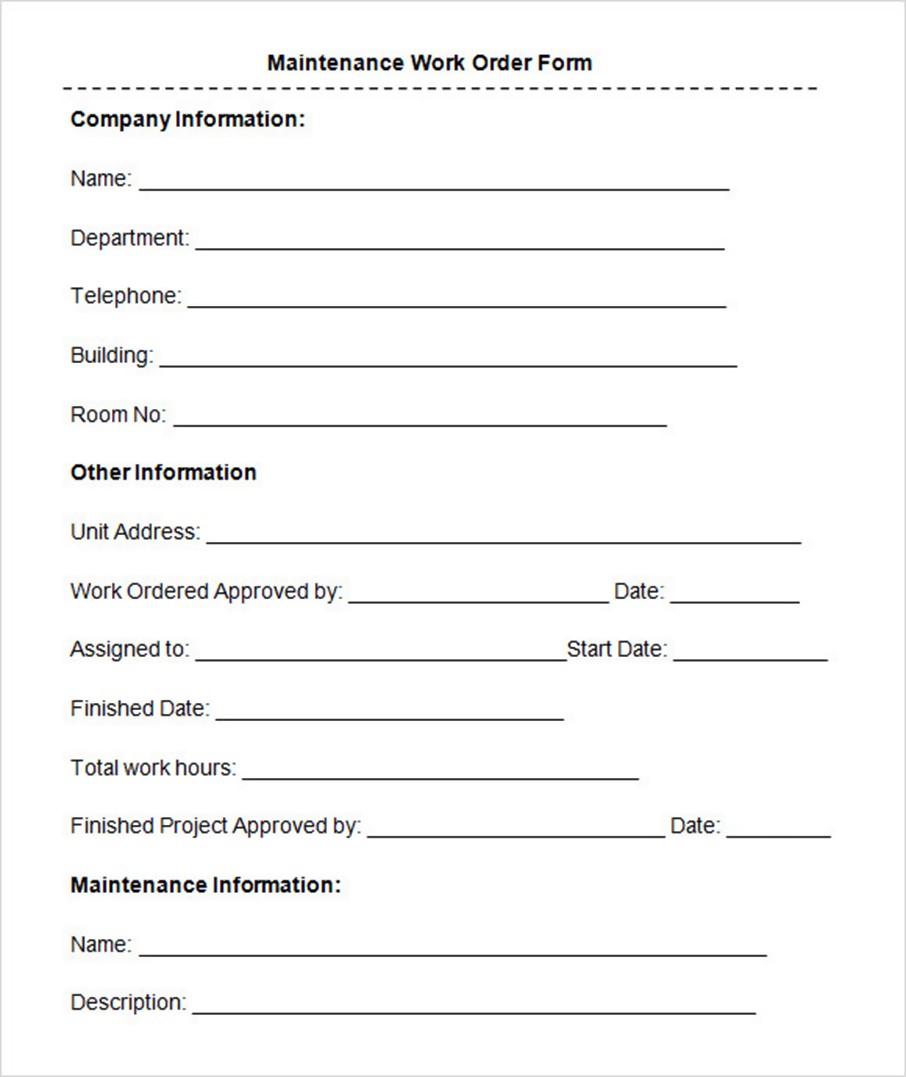

To get a clear picture and boost your visualization when designing a form, see the maintenance work order template below:

A maintenance work order is a unique business document that optimizes your entire maintenance team and enables you to identify critical repair tasks, thus enhancing job prioritization. Indeed, it is an invaluable business tool.

ProsperForms – work order software. Get Started Now